Description

Description

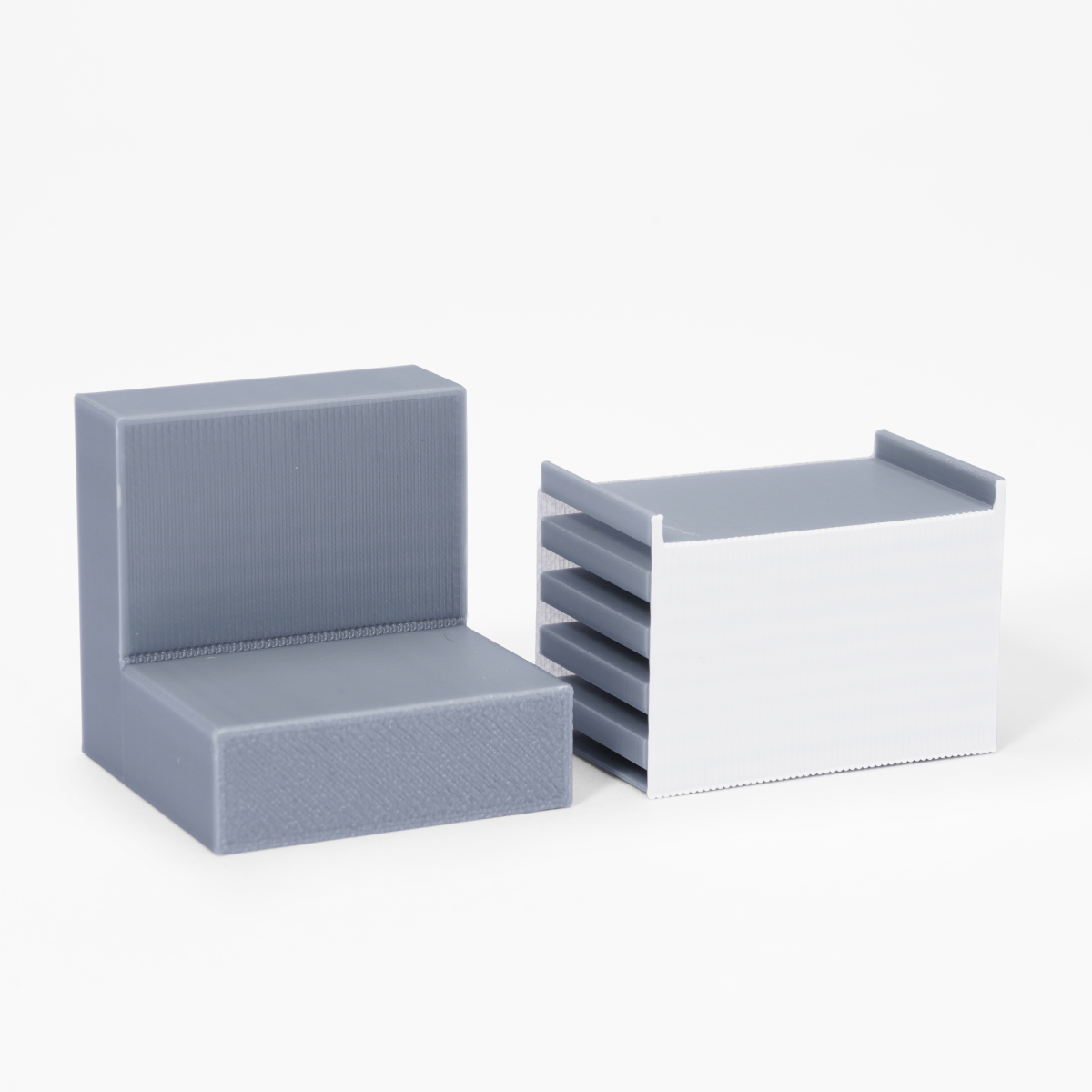

Bambu Support for PLA (New Version)

Bambu Support for PLA is fully compatible with all Bambu Lab PLA filaments and Bambu Lab printers, offering effortless peel-off removal, smooth interface quality, with reliable performance. It eliminates the need for post-processing, saving time while delivering flawless results. All at a budget-friendly price. Upgrade your 3D printing experience today!

Product Features

- Effortless Removal

- Preserve Every Detail

- Affordable Choice

- Use for Support Interface

- Comes with Basic Reusable Spool

- Diameter: 1.75 mm +/- 0.05mm

Cautions for Use

- Only Used for Printing the Support Interface

- Avoid Printing Individual Models

- AMS & AMS lite Compatible

Effortless Removal

Bambu Support for PLA is specifically designed for PLA filaments, ensuring clean, residue-free removal by hand. Say goodbye to post-processing and enjoy a seamless 3D printing experience.

Preserve Every Detail

With optimized support interface settings* in Bambu Studio, Bambu Support for PLA delivers an ultra-smooth contact surface that protects intricate details as if untouched. Perfect for delicate designs, overhangs, and bridges, it ensures premium quality from start to finish.

* 0mm top interface spacing and 0mm Z-distance settings

Affordable Support, Premium Performance

Bambu Support for PLA delivers enhanced performance at 34% less cost than its predecessor. Enjoy greater stability, improved printability, and better results, all while saving money.

Use for Support Interface

Activate the "Support/raft interface" setting in Bambu Studio to apply support material exclusively to contact surfaces. This approach minimizes material usage, saving both time and money.

Accessory Compatibility

| Recommended | Not Recommended | |

| Build Plate |

Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate

|

/ |

| Hotend | All Size / Material | / |

| Bambu Liquid Glue / Glue Stick | Bambu Liquid Glue / Glue Stick | / |

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 55 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 220 - 230 °C |

| Bed Temperature (with Glue) | 35 - 45 °C |

| Printing Speed | < 200 mm/s |

| Physical Properties | |

| Density | 1.33 g/cm³ |

| Vicat Softening Temperature | N / A |

| Heat Deflection Temperature | N / A |

| Melting Temperature | 190 °C |

| Melt Index | 13.6 ± 1.2 g/10 min |