At HartSmart, our experience with various 3D printers—ranging from hobbyist models to industrial machines—revealed a common issue: most printers had limitations and compromises. We needed a solution that met the high standards of our own printer farm that could serve diverse professional needs. Thus, the HSPI-1 was born.

Elevate Your Printing with Advanced Dual-Extrusion

The HSP1-I is our most advanced 3D printer, designed to meet the needs of high-performance printing with its Independent Dual Extrusion (IDEX) system. This innovative feature allows you to use two separate printheads, enabling you to work with multiple materials simultaneously. Imagine creating intricate parts with dedicated support materials like soluble or breakaway supports, all while enjoying fast and reliable printing.

Impressive Build Volume and Easy Setup

Key Features for Optimal Performance

Dual-Extrusion Flexibility (IDEX):

Dual-Extrusion Flexibility (IDEX):

Print complex geometries using two materials at once. Perfect for creating detailed parts with support structures that are easy to remove.

Reliable and Precise:

Reliable and Precise:

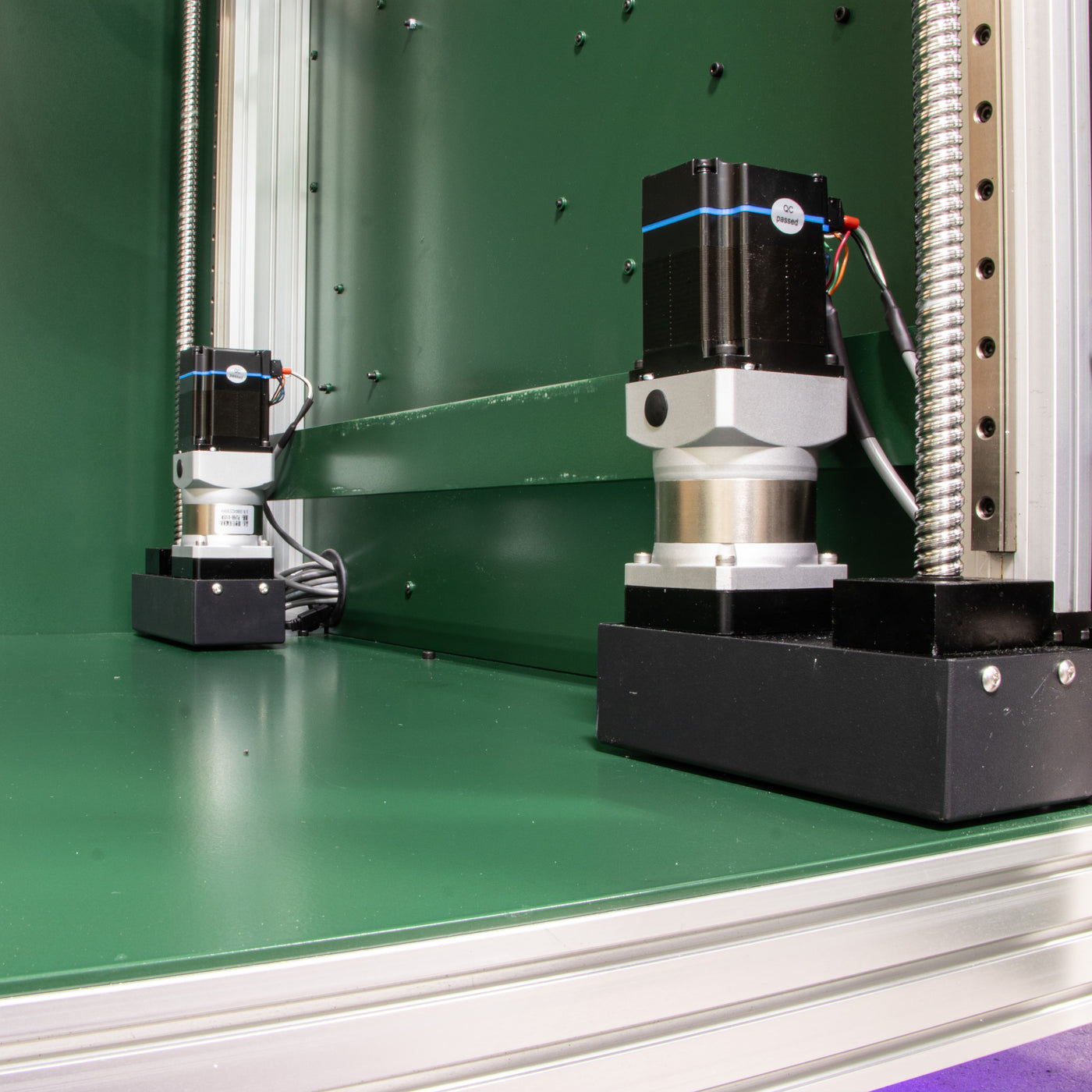

Equipped with closed-loop stepper motors and high-precision components, the HSPI-1-I ensures accurate and consistent results with every print.

Integrated 10kg Spool Storage:

Integrated 10kg Spool Storage:

Store up to two 10kg spools inside the printer for a tidy workspace. Alternatively, use a PrintDry Pro for active filament drying during printing.

Advanced Air Filtration:

Advanced Air Filtration:

Comes with a BOFA air filtration system, housed inside the printer, to safely handle all materials without concerns about VOCs.

Versatile Networking Options:

Versatile Networking Options:

Connect via Wi-Fi or Ethernet for flexible networking, or use the printer offline for secure operations.

Expert US-Based Support:

Expert US-Based Support:

Our knowledgeable support team in the USA is ready to assist with prompt and expert help whenever you need it.

HSP1-I Package Comparisons

Package configurations available range from $45K-$85K.

Discover which package offering best fits your needs!

Discover the HSPI-1, the advanced 3D printer that combines high-speed performance, versatile dual-extrusion capabilities, and unparalleled reliability, designed to meet the needs of professionals and elevate your printing projects.

-

Build Volume

X: 650mm / 26in

Y: 640mm / 25in

Z: 1,000mm (1 Meter) / 40in -

Machine Dimensions

X: 1,320mm / 52in

Y: 890mm / 35in

Z: 1,930mm / 76in(Fits through a 36" doorway!)

-

Electrical & Networking

Works with a standard 120VAC 15A Circuit (Grounded)

Full Industrial Breaker Protection

Networked with WiFi or Ethernet, and also works without being on a network

-

Electronics

Duet 3 Controller Platform

Open Source RepRap Firmware

Filament Detection & Clog Sensors

Closed-Loop Stepper Motors on all 3 axes (X, Y, and Z)

High Precision Bed Level Sensor

Independent Tilt and Mesh Bed Leveling

-

Mechanical

Print Resolution: >50 microns

Print Speeds up to 300mm/s, Travel Speeds up to 800mm/s

Z-Axis Driven by 4 Independent Ballscrews with a 10:1 Gearbox

X and Y Axes Driven by High Speed GT2 belts

Independent Dual Extrusion (IDEX) on Y-Axis

-

Printheads

Dual Printheads, Independently Controlled (IDEX)

1.75mm Diameter Open Filament Compatibility

Dual Takoto HE20 Hotends

Abrasion-Resistant Nozzles

Dual 50-Watt Industrial Heaters, For 100 Watts of Total Heating Power per Printhead