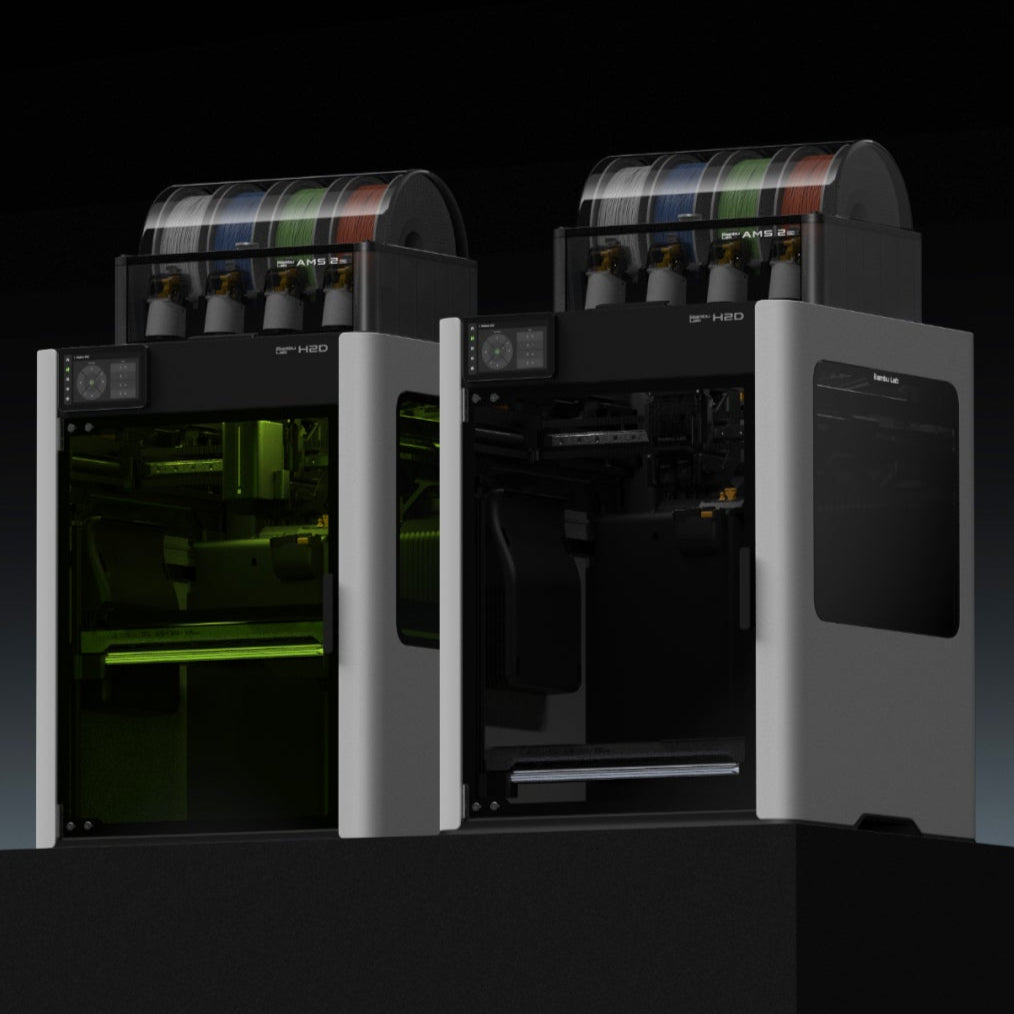

Bambu Lab H2D Dual Nozzle 3D Printer

Description

Description

Bambu Lab H2D 3D Printer with Automatic Material System (AMS)

Rethink Personal Manufacturing

The Bambu Lab H2D is more than just a 3D printer--it's a personal manufacturing hub. As a 3D printer it offers dual nozzles to help reduce printing times and waste with multiple materials, as well as the largest build volume of any Bambu Lab 3D printer to date. But the H2D goes beyond 3D printing as well, offering an optional laser cutting & engraving module, vinyl cutter attachment, and even pen drawing capabilities, all in the same machine.

Why Buy a Bambu Lab Printer From HartSmart Products?

HartSmart Products (HSP) is more than just an authorized reseller of Bambu Lab printers, parts, accessories, and filament. HSP is also an authorized Repair Center and even an authorized Warranty Center for Bambu Lab. If anything goes wrong with your printer we're able to get customers up and running quickly with our Iowa, USA team and inventory of warranty parts. You simply get more when you buy from HSP!

Check out our HSP Bundle to get filament and parts for your H2D at a discount when buying the bundle! Our HSP Bundle includes:

- Bambu Lab H2D 3D Printer

- Bambu Lab AMS 2 Pro

- Bambu Lab Spare Textured PEI Build Plate

- Bambu Lab Spare 0.40mm Hardened Steel Hotend

- Magigoo Original Bed Adhesive, 120ml Bottle

- 4x 1kg Spools of HartSmart Products' own Layer Line Filament Engineering PLA

- 1x 1kg Spool of Bambu Lab Support for PLA/PETG

- 1x 1kg Spool of Bambu Lab ABS-GF

- 1x 500g Spool of Bambu Lab Support for ABS

- 1x Pack of 4 AMS Spool Weights

Features:

- Dual-nozzle Multi-material 3D Printing

- Optional 10W/40W Laser and Cutting Module

- 350*320*325 mm³ Print Volume

- 5μm Resolution Optical Motion Calibration

- Closed-loop Servo Extruder

- 350°C Nozzle & 65°C Active Chamber Heating

- Voltage Range: 100-120 V

Dual Nozzle Capabilities

Flexible and Rigid, low cost and exotic materials in a single print.

Dedicated Support Material for perfect supports with minimal waste, purging, and reloading.

Efficient Multi-Color Printing, reducing print times and material waste.

All-in-One Solution for Personal Manufacturing

Laser Modules in either 10W or 40W for engraving and cutting.

Digital Cutting - Precise cutting on a variety of materials.

Pen Drawing Capability for Drawing and Writing

Live Spatial Arrangement

The H2D's BirdsEye camera, combined with computer vision algorithms, delivers top-view alignment accuracy up to 0.3mm. This advanced spacial alignment allows users to place the tool path at the right position on the material - Truly "what you see is what you get."

Auto Arrangement - Maximize Material Efficiency, Minimize Waste

Leveraging real-time images from the BirdsEye camera, Bambu Suite can automatically arrange your project according to the shape of your material, ie-leftover plywood from the previous project. This feature helps you get the most out of every material.

Don't Worry About Safety - We've Got You Covered

Laser Safety Windows allow you to operate and monitor laser projects safely without the need for goggles, thanks to our safety windows.

An optional Air Purifier ensures clean air, even during indoor laser operations.*

A Serious Laser Machine

Air Assist improves surface quality by directing high-speed air to cool the laser path, ensuring cleaner and more precise results.

Contact-less 3D Mesh* uses advanced optical heigh measurement to create a detailed 3D mesh without physical contact, enabling precise laser work on curved surfaces.

Go Big, Go Fast, Go Precise

50um Ultra-Fine Motion Accuracy* with the ultra-accurate vision encoder plate, combined with 5um resolution optical measurements to track and correct toolhead motion enables the H2D to achieve consistent and reliable distance-independent 50um motion accuracy across the entire workspace, one order of magnitude better than its predecessor. (*Vision Encoder sold separately)

King-Size Work Zone

With a print volume up to 350mm x 320mm x 325mm*, creating large-scale projects has never been easier! From laser engraving on sizable objects to printing oversized models, the expanded capacity empowers you to bring even your most ambitious idea to life.

Maximum Volume:

Single-Nozzle Printing Volume:

Dual-Nozzle Printing Volume:

Unleash the Full Potential of High-Performance Materials

350C Hotend and 65C Chamber Heating enables the H2D to deliver precise closed-loop temperature control. This advanced system effectively eliminates warping and deformation in high-performance materials, ensuring superior layer bonding and maximizing their full potential.

REAL High-Flow Hotend*

Consistently print at 600mm/s with ease. The H2D's purpose-built high-flow hotend ensures reliable, high-speed printing at 600mm/s. Designed for consistent performance, it eliminates mid-print flow rate restrictions, enabling uninterrupted high-speed printing regardless of the print size or complexity.*

DynaSense Extruder - Intelligent Sensing for Precise Extrusion Control

Bambu Lab's proprietary PMSM servo architecture establishes an intelligent extrusion governance system. It executes 20kHz Torque/Resistance and position sampling to dynamically modulate electromagnetic torque vectors. Stabilizing extrusion and detecting filament grinding and clogging.

Nozzle Camera to Monitor Extrusion at the Nozzle Tip