Vision Miner 22IDEX V4 High Temp 3D Printer

Description

Description

Vision Miner 22IDEX Version 4 High Temperature 3D Printer

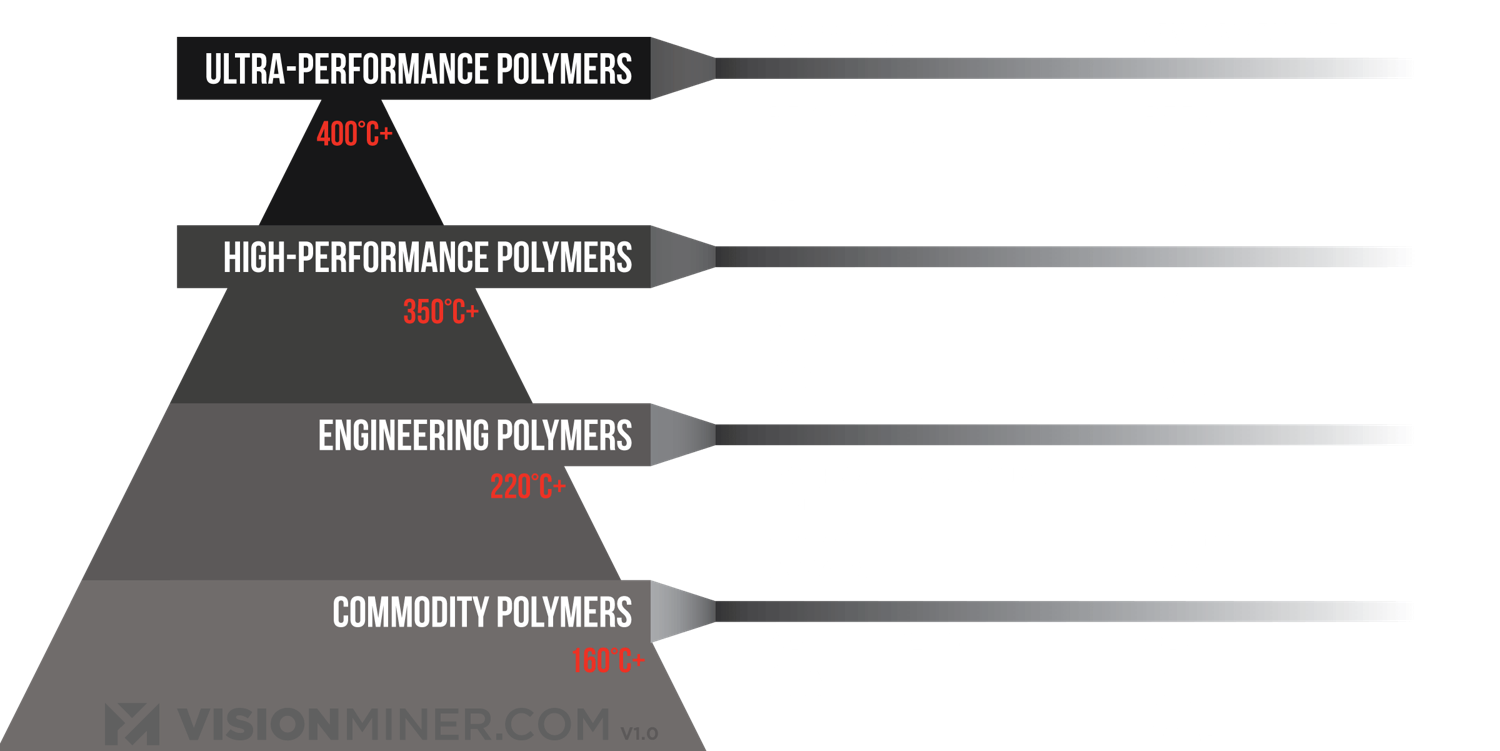

INDUSTRIAL 3D PRINTER: UNLIMITED POLYMER OPTIONS

PEEK • PEKK • ULTEM™ • PEI • NYLON • PC • ABS • +MORE

With dual independent extruders capable of 500ºC, an actively-heated chamber reaching 100ºC, and a triple-motor, true-self-leveling 200ºC bed, coupled with the fully open material system, the 22 IDEX v4 unlocks another level of automation, ease-of-use, and affordability for high-temp additive manufacturing.

High-Performance Materials, Straight Out of the Box

Why v4?

The 22 IDEX v4 takes the proven v4 foundation and adds usability, security/compliance, and future expandability—without pushing you into a six-figure ecosystem or proprietary materials.

Open Material System

Not locked to vendor specific filaments

True IDEX Printing

for multi-material, soluble supports, duplication, and mirror modes—effectively two printers in one.

Improved Useability

100+ micro-adjustments to improve the overall user experience.

Improved Thermals

Higher temperatures for reliable 3D printing of ultrapolymers

We use our own machinery in our service bureau every day -- taking our own experiences, along with that of our customers, ranging from Fortune 500 companies to independent fabrication shops, and made the 22 IDEX better than ever before.

STRONG Parts. Functional Polymers.

Parts you can sell, materials you can print jigs and fixtures from, vacuum molds, press brake tooling - if it can be 3D printed, there's a good chance you can do all that and more, on the 22 IDEX v4.

- Aerospace-grade replacement parts, tooling, fixtures

- Autoclavable, sterilizable tools for medical applications

- Rigid, chemical & radiation resistant polymer composites

- High-temp, metal-replacement thermoplastics

Under-the-hood in race cars, to satellites in space - whether you're a one-man operation, or a 20,000+ employee aerospace company, this machine can get your job done.

HARDWARE FOR ADVANCED USERS

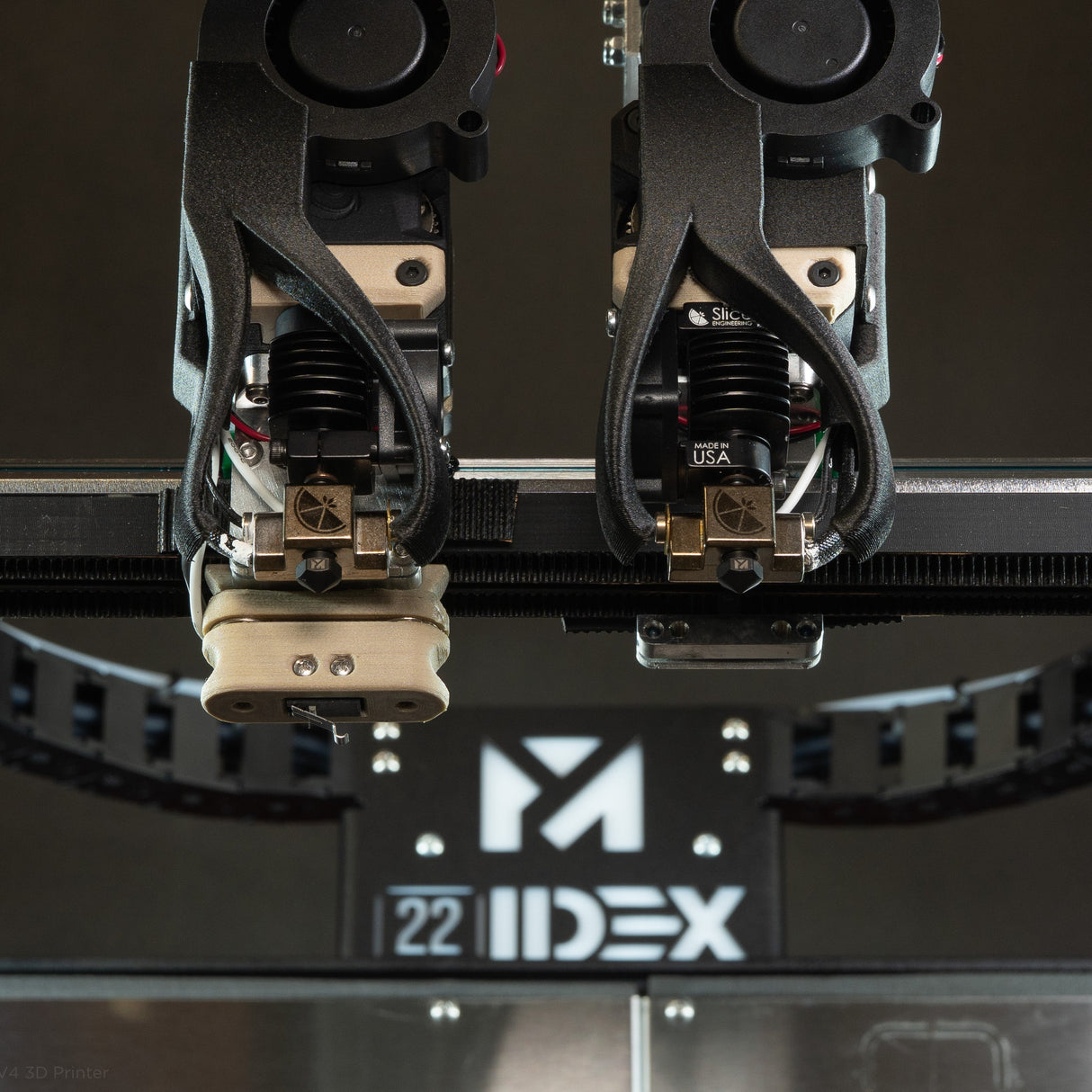

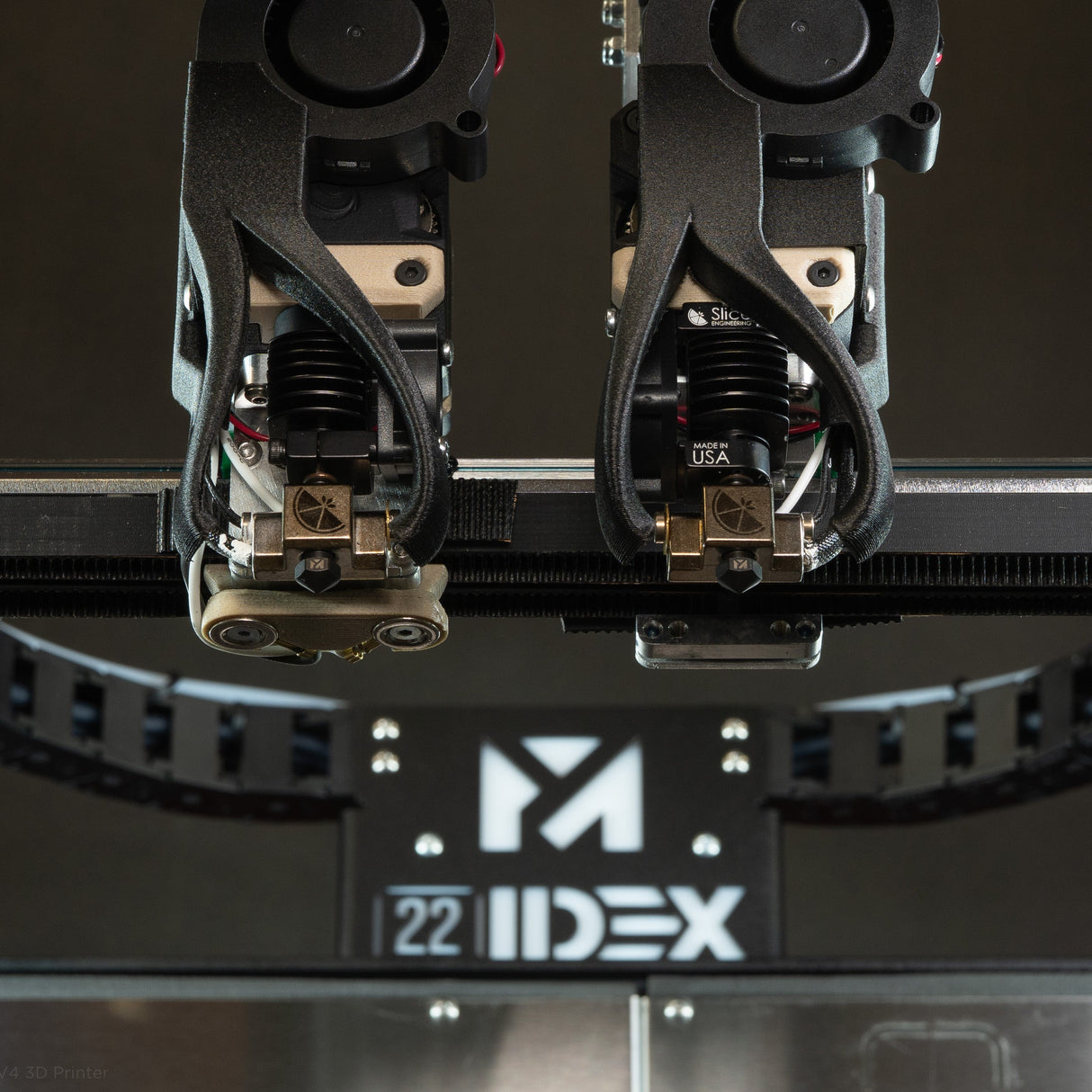

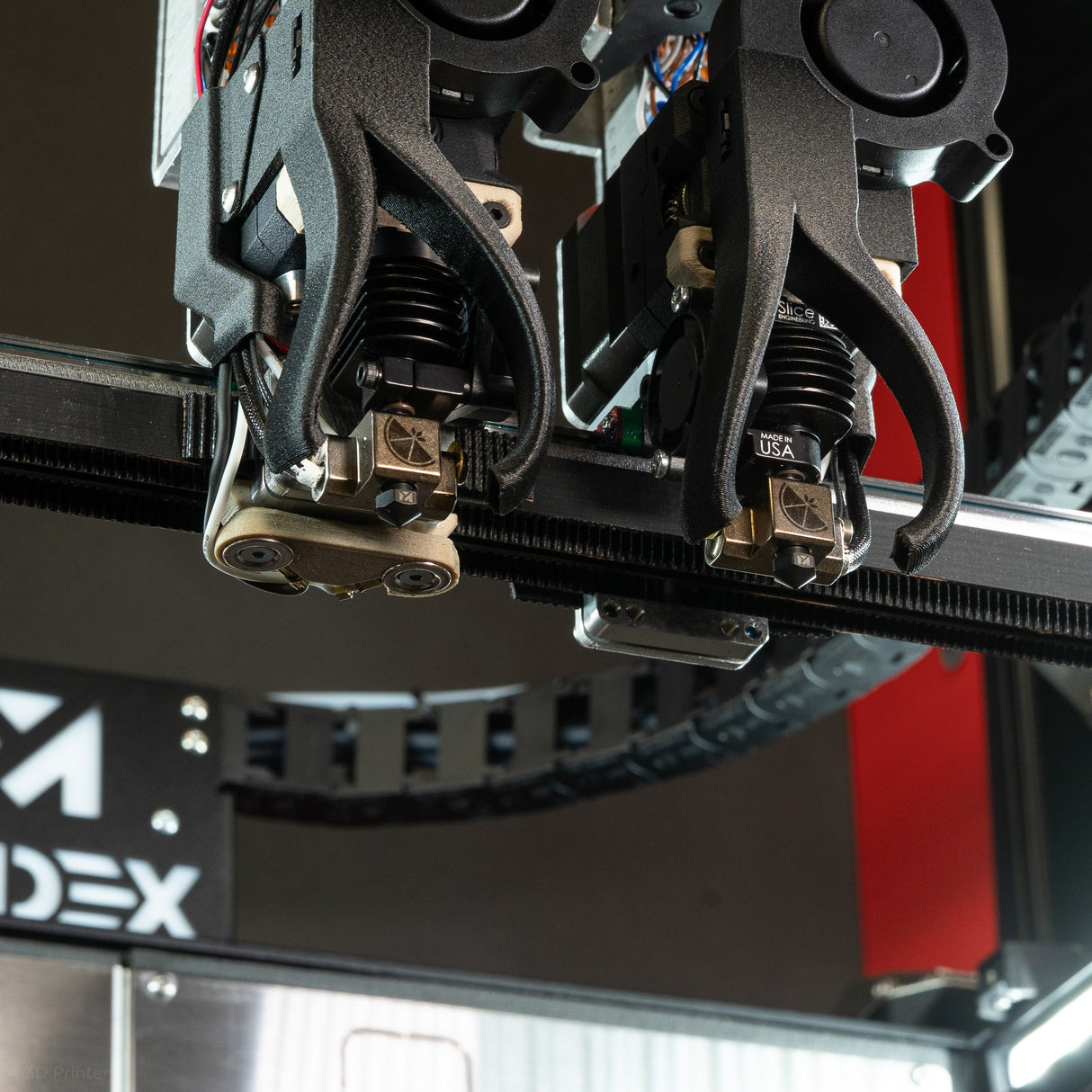

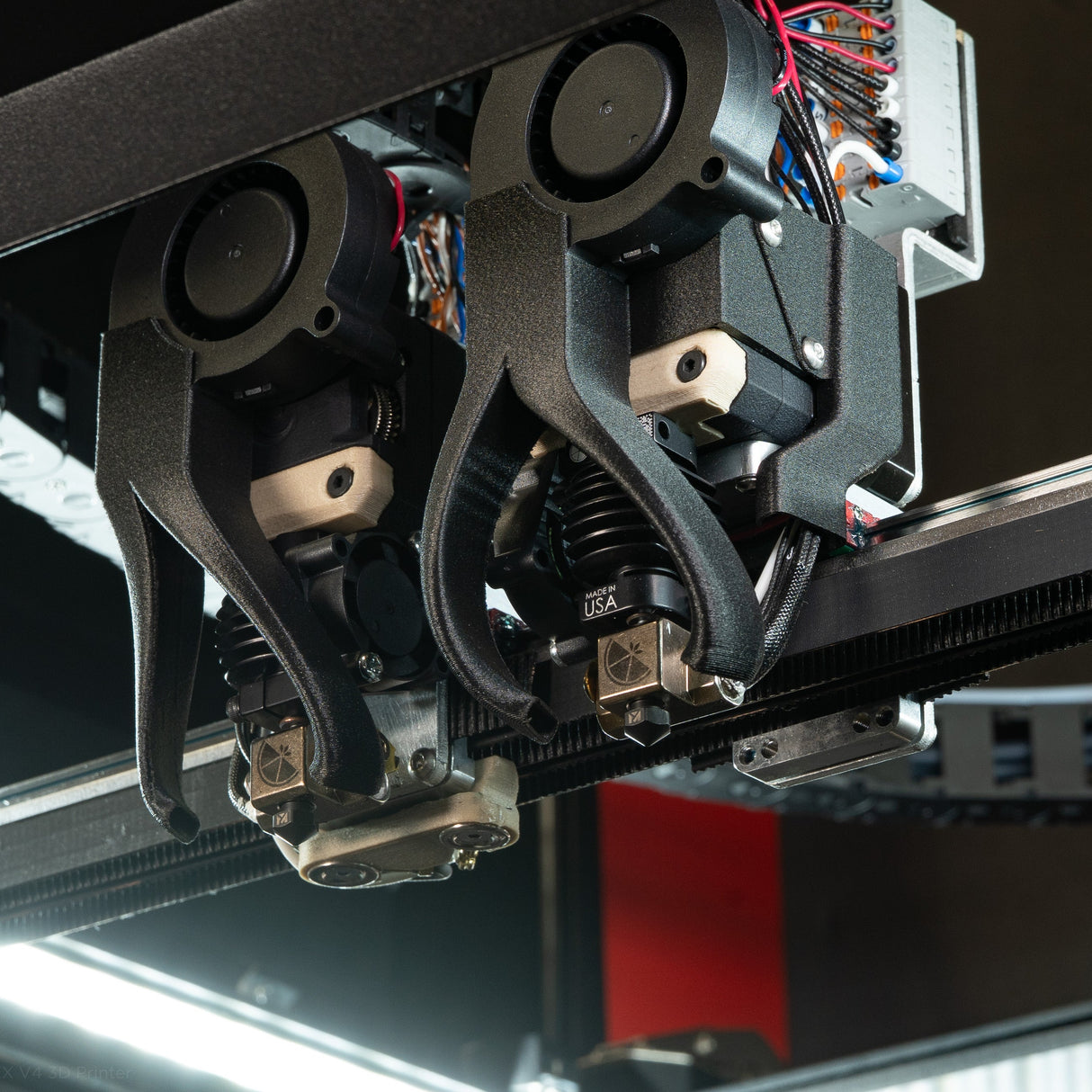

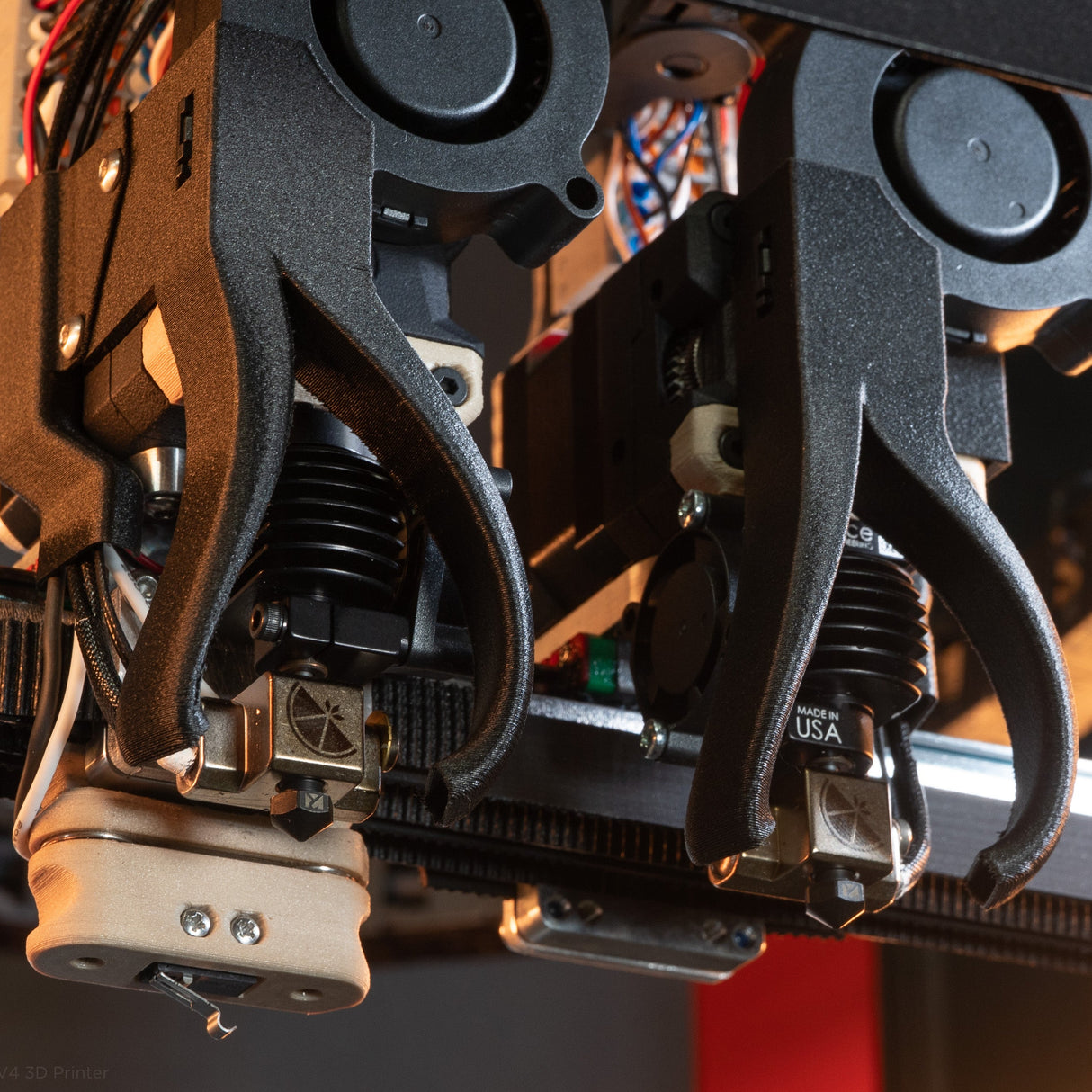

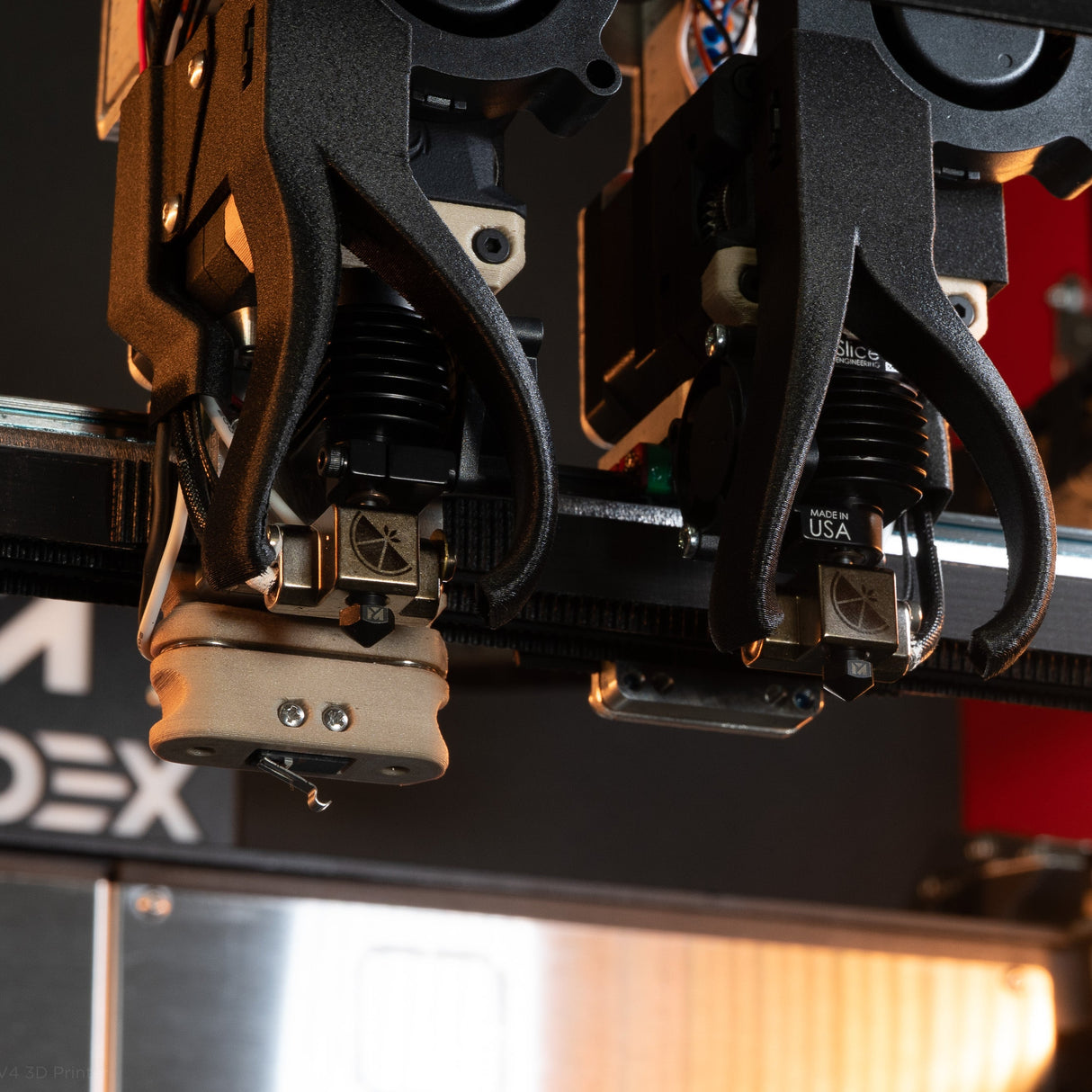

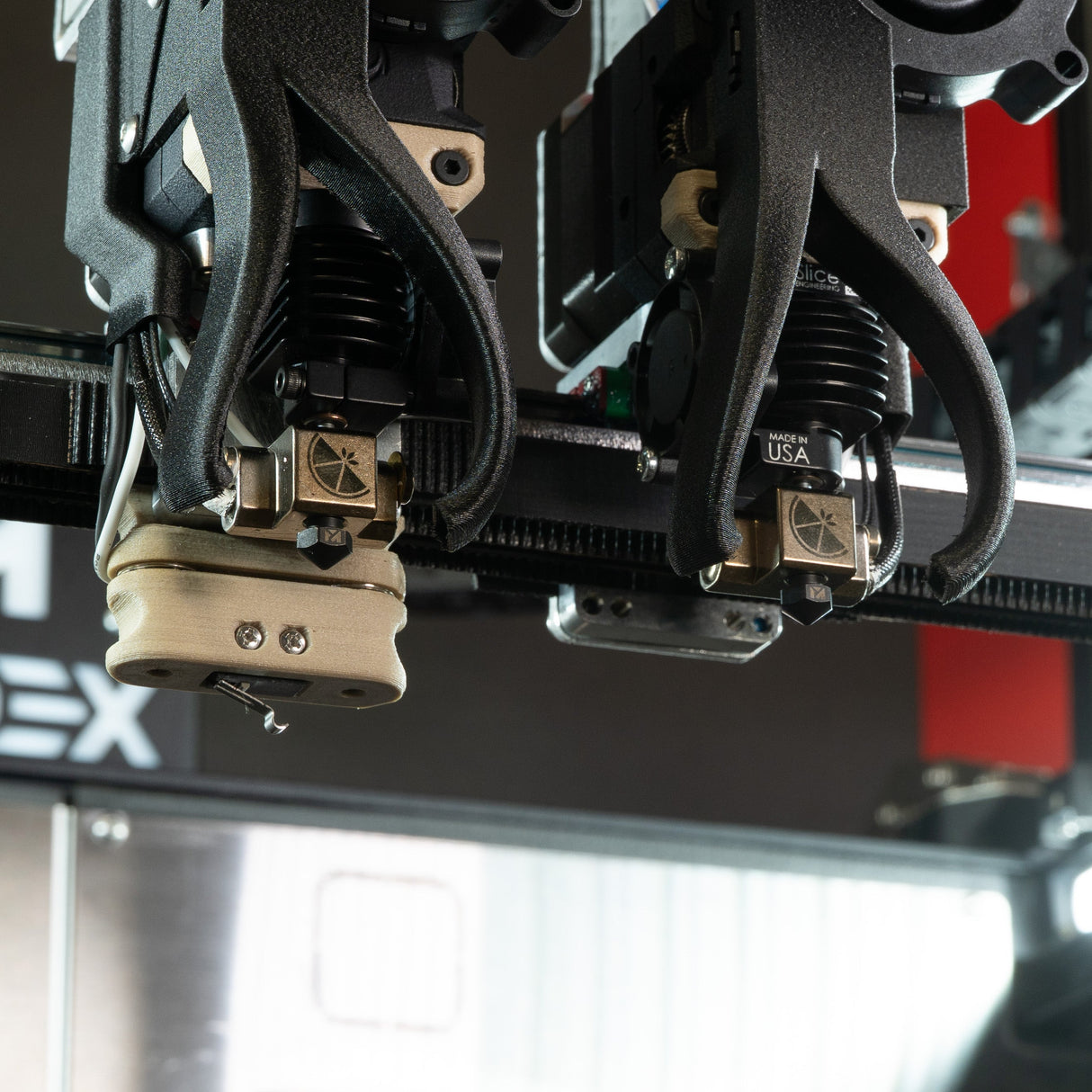

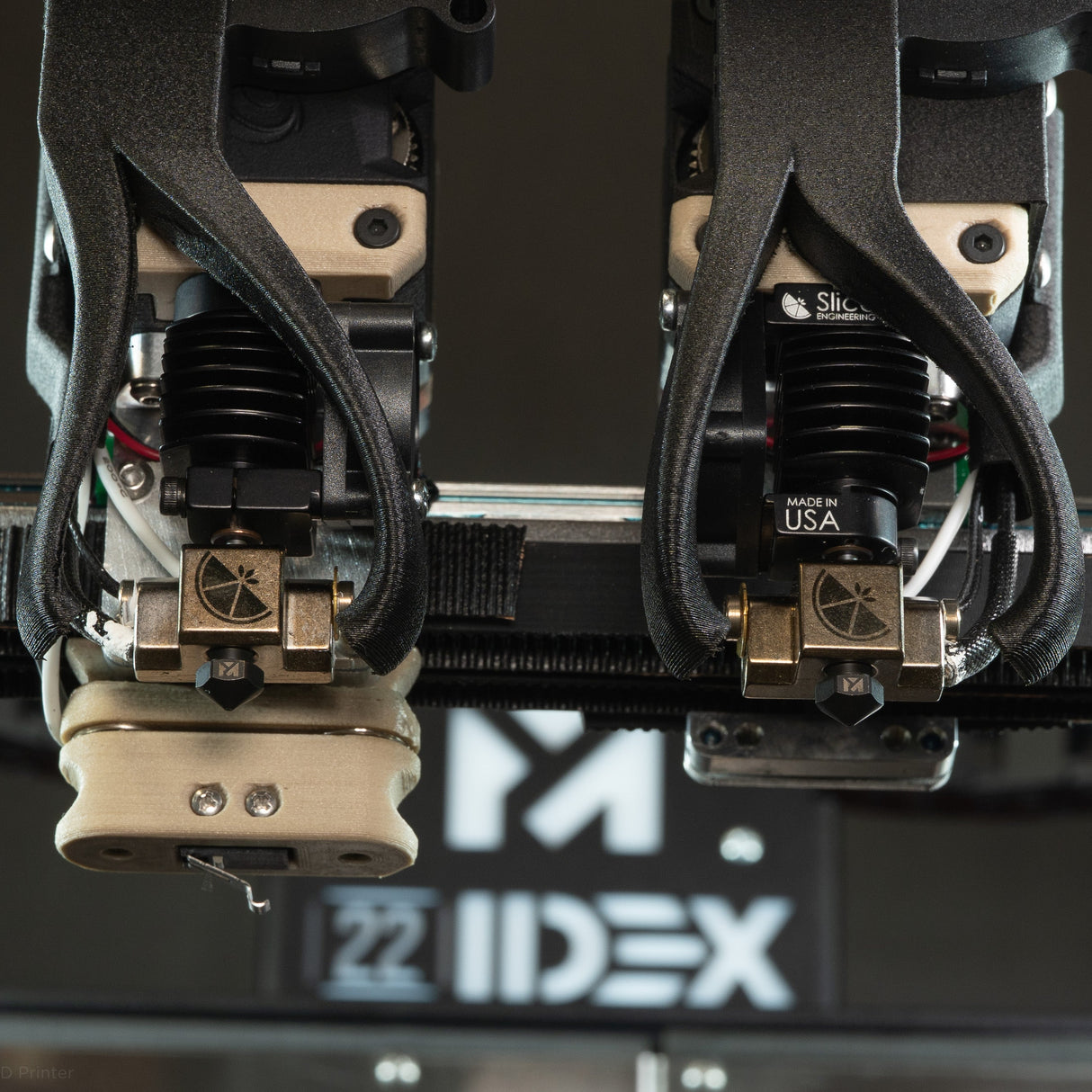

500ºC Nozzles

Independent Dual-Extruder Hotends

Maximum temperatures give you the ability to print any Performance Thermoplastic on the market, from PLA to PEEK, PEKK, ULTEM™ , PPSU, and more.

Unlike other machines, BOTH hotends reach the full 500ºC, enabling multi-material, duplication mode, mirror mode, and full use of supports - soluble and otherwise.

200ºC Build Platform

True Self-Leveling Build Platform

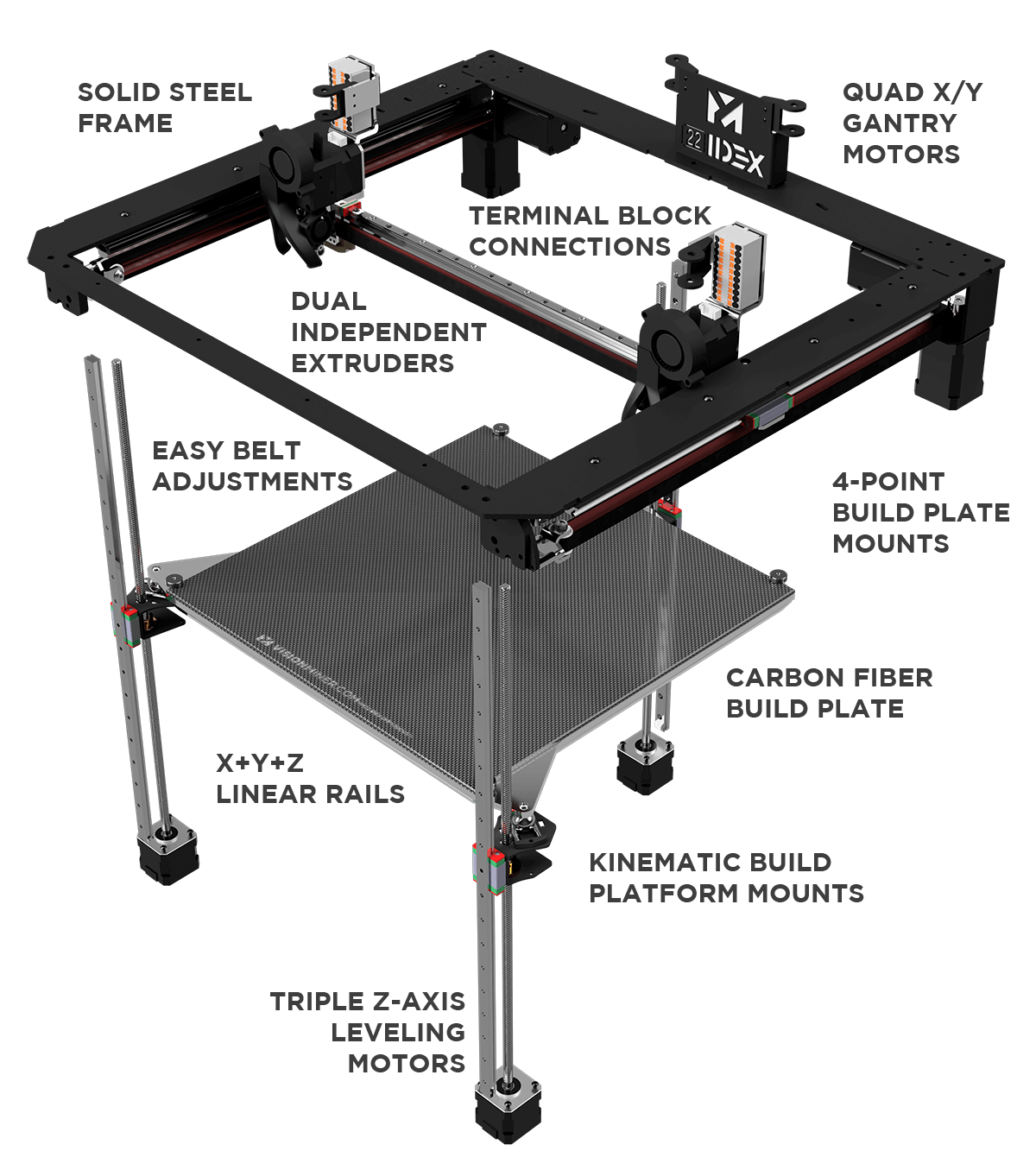

Never manually level your bed again. Triple Z-Axis motors enable true self-leveling of the build platform, combined with 128-point+ mesh leveling (technically unlimited points), so the hotends will compensate for any variation in the build surface.

On top of that (literally), the QUAD-motor XY gantry squares itself -- your parts will maintain accuracy over time, without having to constantly recalibrate.

100ºC+ Chamber

Actively Heated Chamber

Performance thermoplastics are next to impossible without a heated build environment - the 22 IDEX heats up to 100ºC+, enabling functional high-temp materials with solid mechanical properties. Dual chamber thermistors monitor the temperature, with auxiliary convection fans ensuring an evenly-heated build volume.

Unlimited Materials

1.75mm Open-Filament FFF/FDM System

Not locked into proprietary materials, limited nozzle temperatures, or overly-expensive branded filaments... we carry the best materials we can find, at Vision Miner, from several sources -- but you're ALWAYS welcome to use your own. FAR 25.853, UL94 V0 rated materials, and more.

Unlocked Firmware

Up-to-date RepRap firmware on Duet 3

The latest and greatest firmware comes installed on your 22 IDEX, and there are always up-to-date links to the latest versions available in our documentation.

CUTTING-EDGE MOTION SYSTEM

A TOTALLY UNIQUE, QUAD-MOTOR X/Y-AXIS, TRIPLE-MOTOR Z-AXIS

- Solid Steel Frame - Stable and dependable, it won't shift as it soaks heat -- critical at high temperatures

- Terminal Block Connections - No need to hunt down specialized connectors -- easily swap, replace, or modify components

- 4-Point Build Plate Mounts - No matter which build plate material you're using, rest assured that it's not going to warp up with your ultra-performance parts.

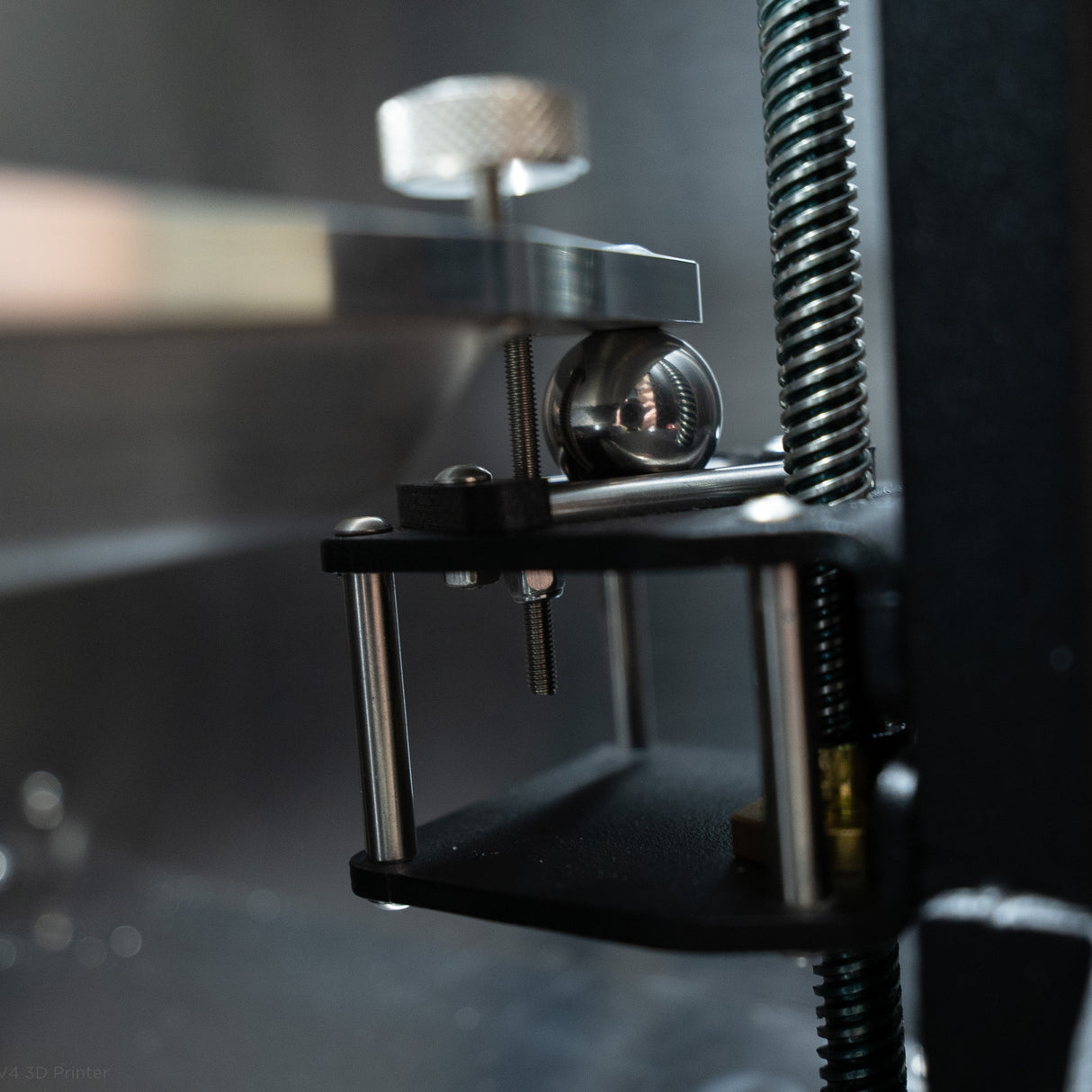

- Kinematic Z-Axis Mounts - Self-centering, kinematically-coupled build platform -- always true, always solid, automatically self-leveling

- Easy-Access Belt Adjustment - The belt adjustment pulleys are easily accessed at the front, making it quick work to adjust them as-needed. Did we mention the ultra-stable 12mm Kevlar belts?

MADE FOR ENGINEERING Materials: USE THE WIDEST RANGE OF PERFORMANCE THERMOPLASTICS

INDUSTRY-LEADING FEATURES

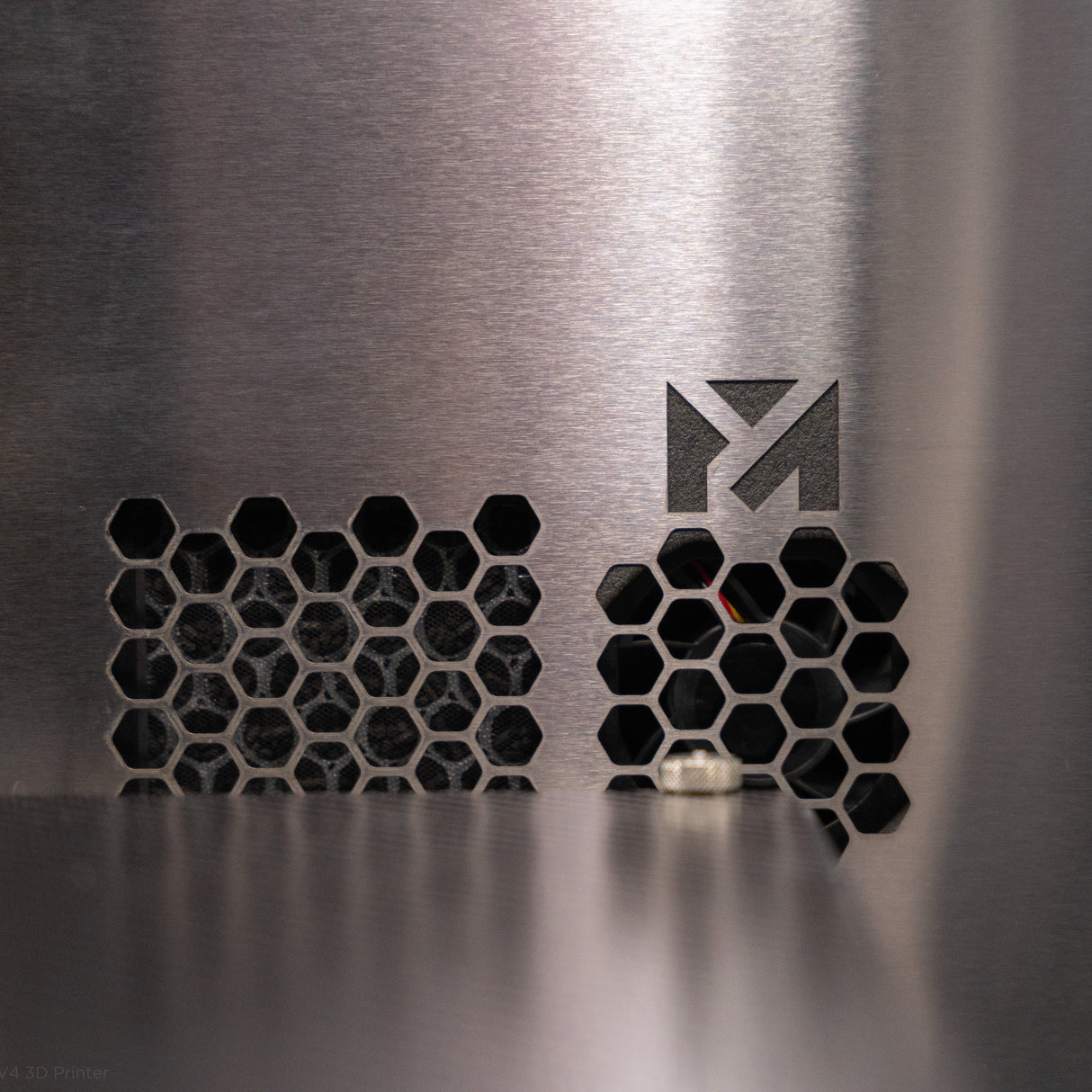

FUME EXTRACTION - CLEAN AIR

Many 3D printers include air filters, which are usually HEPA filters and a thin sheet of activated carbon. This simply isn't enough for a production environment, barely passing as filtration at all -- the 22 IDEX comes standard with hookups for 2" hoses, for connecting to industrial fume extraction systems.

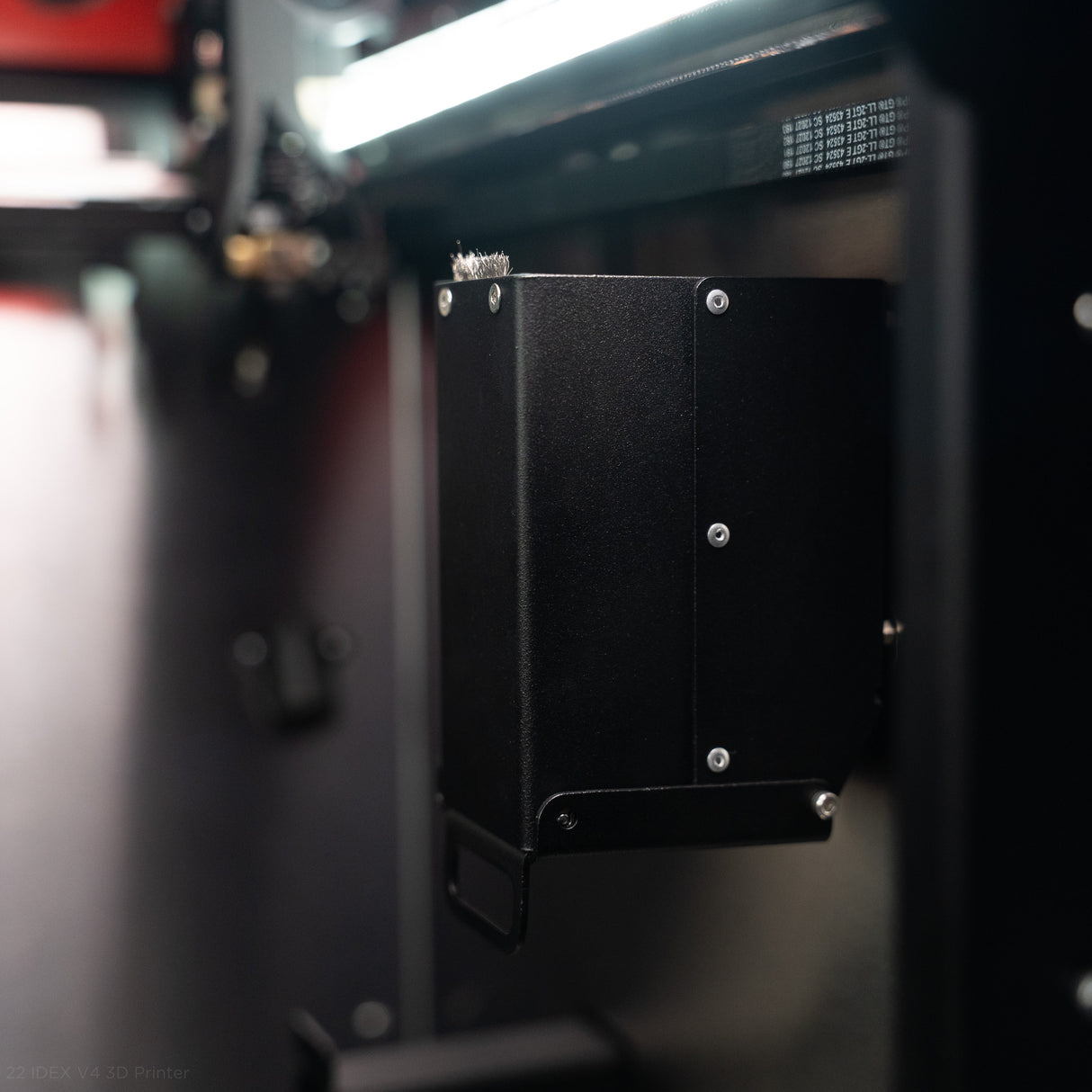

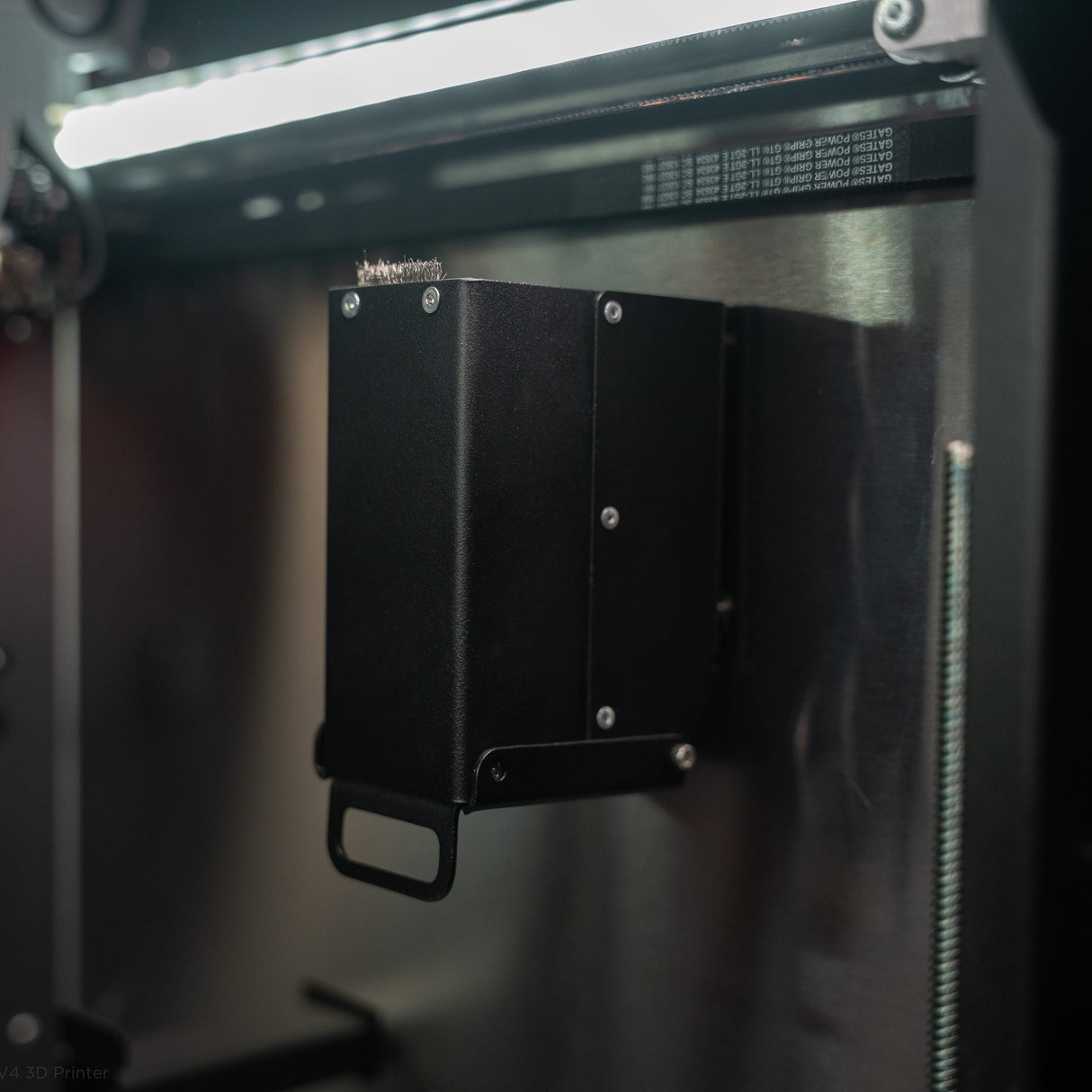

XY TOOLHEAD - AUTO ALIGNMENT

Our automated XY toolhead alignment eliminates the older style of having to do multiple alignment prints. Pulling from proven, precision practices of the CNC Industry, our Auto Alignment probe takes the guesswork out of the picture with one easy, automated process.

Built-in Automatic Filament Drying System

The filament on the 22 IDEX is stored inside the chamber while printing -- this means that when using the heated chamber with hygroscopic filaments (read: most filaments), the filament is kept dry, eliminating much of the oozing, blobbing, and poor surface finishes due to moisture.

Auto Shutoff and Safety Systems

Safety is paramount, in the workplace and workshop - the printer will automatically shut down if it senses overheating, thermal runaways, or electrical errors. Solid State Relays and quality wires are just a fraction of the safety features designed into the machine, from the ground up.

AMERICAN SERVICE & SUPPORT

We're here to help you -- that's our promise, if you succeed, we succeed.

No scripted auto-attendant generic answers, just real people with real problem-solving skills. We work via phone, email, and video conferencing to ensure whatever your problem is, we get you back up and into production time as quickly as possible. We don't spoon-feed basic fundamentals (that's what our video training and docs are for), but we are always here to help.

Technical Specification of 22IDEX V4

22IDEX Bundle Options

Maintenance Bundle - $15,584.99

- 1x 22IDEX V4

- 4x Copperhead Heat Break

- 2x 0.40mm Hardened Steel Nozzle

- 2x Copperhead Hot Block

- 4x Heatsink Fan

- 2x Part Cooling Blower Fan

- 1x Chamber Circulation Fan

- 2x Industrial Heater(50W 24V)

- 4x PT1000 Thermocouple

- 1x Build Plate Thermistor

- 2x Nano Polymer Adhesive

- 1x Z-Probe Wire

Professional Bundle - $18,900.00

- 1x 22IDEX V4

- 2x Copperhead Hotends (Full Assembly)

- 10x Copperhead Heat Break

- 1x Carbon Fiber Build Plate

- 1x Filament Drying Kit (Chamber + Pump only)

- 4x 0.40mm Hardened Steel Nozzle

- 4x 0.60mm Hardened Steel Nozzle

- 4x 0.80mm Hardened Steel Nozzle

- 4x Hot Block

- 4x Heatsink Fan

- 2x Part Cooling Blower Fan

- 1x Chamber Circulation Fan

- 2x Industrial Heater(50W 24V)

- 6x PT1000 Thermocouple

- 1x Build Plate Thermistor

- 6x Nano Polymer Adhesive

- 1x Z-Probe Wire

- 2x Z Probe Grounding Wire

- 1x (1yr) Extended Warranty

- 1x (3mo) Tier 3 Support

Production Bundle - $18,900.00

- 1x 22IDEX V4

- 4x Copperhead Hotends (Full Assembly)

- 10x Copperhead Heat Break

- 1x Carbon Fiber Build Plate

- 1x Filament Drying Kit (Chamber + Pump only)

- 1x Industrial Vacuum Oven

- 4x 0.40mm Hardened Steel Nozzle

- 4x 0.60mm Hardened Steel Nozzle

- 4x 0.80mm Hardened Steel Nozzle

- 4x Hot Block

- 4x Heatsink Fan

- 2x Part Cooling Blower Fan

- 1x Chamber Circulation Fan

- 2x Industrial Heater(50W 24V)

- 6x PT1000 Thermocouple

- 1x Build Plate Thermistor

- 6x Nano Polymer Adhesive

- 1x Z-Probe Wire

- 2x Z Probe Grounding Wire

- 1x (1yr) Extended Warranty

- 1x (3mo) Tier 1 Support