Description

Description

MK4S to Prusa CORE One Conversion Kit By Prusa Research

Prusa CORE One Conversion kit contains all parts you need to transform your Original Prusa MK4S into the fully enclosed CoreXY 3D printer, the Prusa CORE One. This kit is compatible with the MK4S only!

The silver PSU is not compatible with the conversion kit.

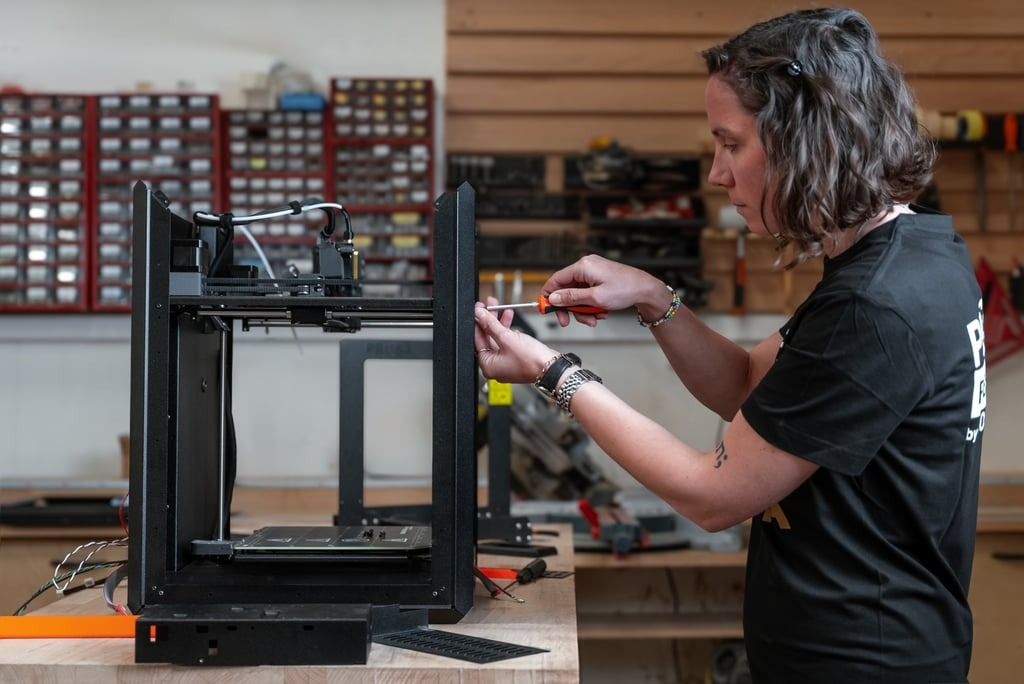

Transform your Original Prusa MK4S into the brand new, fully enclosed CoreXY 3D printer and upgrade your printing experience. Once you’re finished with the assembly, your new printer is going to be not only faster, but it will also take up less space, print larger models and tackle even demanding filaments like PCCF or Nylon without warping. In the Conversion Kit, you will find everything you need to perform the entire process and end up with the Prusa CORE One without any compromise.

The Prusa CORE One utilizes many proven parts from the Original Prusa MK4S. This is why it is possible to convert your existing 3D printer into the new Prusa CORE One, and also why we can offer outstanding backwards compatibility. You can easily reuse your current print sheets, hotends, nozzles, and many other parts.

xLCD Info

Before you order the upgrade, please check which xLCD electronics your printer came with. This is important for correct compatibility with the upgrade. Depending on the selected options, we can send you additional components to ensure compatibility with the upgrade.

- The top image is of the NEWER version of the xLCD. If you have this version please choose the "MK4S -> CORE One (for newer version of xLCD)" option in the menu on the right.

- The bottom image is of the OLDER version of the xLCD. If you have this version please choose the "MK4S

-> CORE One (for older version of xLCD)" option in the menu on the right.

Flawless Precision

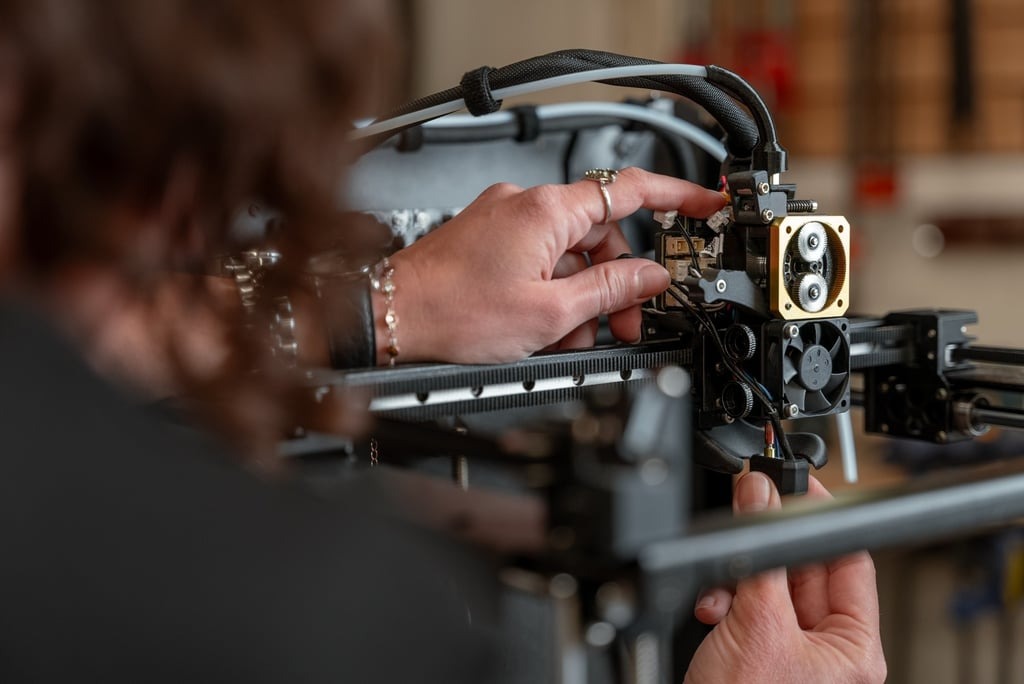

Outstanding print quality thanks to the Nextruder

You can be sure that with our internally developed, quality-focused print profiles, your models will turn out exactly the way they were designed, with perfect dimensional accuracy. CORE One takes advantage of the upgraded Nextruder with 360° cooling that enables flawless printing of 75° overhangs, saving both time and material.

Maximum Speed without a catch

The CORE One is fast with every filament, not just specialized ones

Don’t limit your projects with a small selection of specialized “high-speed” filaments. Use any PLA, PETG or any of the advanced materials. While the CORE One is our fastest printer yet thanks to its robust CoreXY kinematics, high-flow nozzle, Input Shaper and factory-tuned print profiles for 200+ filaments, it never sacrifices quality for quicker print times.

Compact Footprint, Large Volume

The perfect fit for any home, workplace or print farm

The Prusa CORE One takes up 50% less space than the MK4S inside an enclosure, yet it delivers an impressive 30% increase in print volume. Space efficiency matters - even for us! With a massive 3D print farm of over 600 machines, the CORE One's compact footprint and optimized design let us fit even more printers into the same space and boost our production.

The Best Solution for Advanced Materials

Print durable functional models easily and without warping!

The chamber is as compact as possible, with a cleverly designed recess on each side to minimize its volume. This allows the chamber to quickly reach higher temperatures (up to 55°C), enabling you to print ASA, ABS, PC, PA (Nylons), and other advanced materials smoothly, without warping. The automatic ventilation system and active temperature control enable flawless printing of PLA - even with the door completely closed!

Robust Steel Exoskeleton

A design that works and looks the Part

Prusa CORE One is built as an all-steel exoskeleton. The enclosure is an integral part of the printer, providing it with outstanding stability and rigidity. However, maintenance is still simple, and if you need to replace a worn part in a couple of years, it’s a complete no-brainer. You can take everything apart with a screwdriver. As usual with us, we hold parts in stock for years.

Technical Parameters

| Measurements | |

|---|---|

| Build Volume | 250 x 220 x 270 mm | 9.8 x 8.6 x 10.6 in |

| Filament diameter | 1.75 mm |

| Layer height | 0.05-0.30 mm |

| Printer dimensions | 22,5 kg, 415×444×555 mm; 16.3×17.5×21.8 in (X×Y×Z) |

| Electronics | |

| Mainboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper Drivers | Trinamic 2130 |

| Stepper motors | Precise 0.9° X,Y stepper motors (prevents VFA) |

| Extruder | |

| Extruder | Nextruder, Direct Drive, E3D V6 compatible (with adapter) |

| Extruder electronics | Custom breakout board for connecting fans, thermistors and other parts. |

| Filament path | Aluminum heatsink, all-metal hotend |

| Drive system | Nextruder Planetary Gear System, 10:1 gearbox ratio |

| Cooling fan | High-performance turbine, 360° cooling system |

| Nozzle | High-flow Prusa Nozzle brass CHT - 0.4 mm |

| Max. operating temperature | |

| Max nozzle temperature | 290 °C / 554 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Max chamber temperature | 55 °C / 131 °F |

| Controls | |

| LCD screen | 3.5″ graphic 65k color screen |

| Touch control | Yes |

| Firmware update interface | USB drive, Prusa Connect, Prusa Mobile App |

| Prusa Connect support | Yes |

| Prusa App for iOS and Android support | Yes |

| Quick-Swap nozzle system | Yes |

| Lighting | Yes |

| Accessories | |

| Internal camera | optional, in-chamber solution |

| MMU3 support | Yes |

| HEPA filtration | optional addon |

| Advanced Filtration System | optional addon |

| GPIO Board compatibility | Yes |

| Accelerometer compatibility | Yes |

| Connectivity | |

| Ethernet connection | Yes |

| Wi-Fi | NFC receiver, optional ESP Wi-Fi module (delivered with the printer) |

| Sensors | |

| Filament Sensor | Yes (2 sensors) |

| Loadcell sensor | Yes |

| Thermistors | 5 high-precision thermistors (genuine Semitec) |

| Fan motors monitoring | Yes |

| Door sensor | Yes |

| Printing | |

| Print medium | USB drive / LAN / internet via Prusa Connect or mobile Prusa App |

| Print surface | Magnetic heatbed with removable PEI spring steel sheets |

| First layer calibration | Fully automatic (thanks to the Load Cell sensor) |

| Bed calibration | Automatic, Mesh Bed Leveling (only on print area) |

| Input shaper | Yes |

| Supported materials | PLA, PETG, Flex, PVA, PC, PP, CPE, PVB and when using the optional Advanced Filtration System ABS, ASA, HIPS, PA |

| Phase Stepping | Yes |

| Power | |

| PSU | 240W |

| Power panic | Custom made by Delta with Power Panic HW |

| Power consumption | PLA settings: 90W / ABS settings: 110W |