Poseidon Gen3 - Hybrid Industrial 3D Printer

Couldn't load pickup availability

Description

Description

Filament Innovations Poseidon 3D Printer

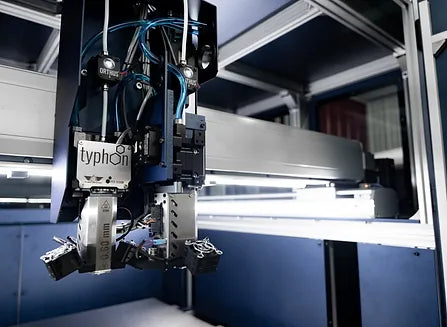

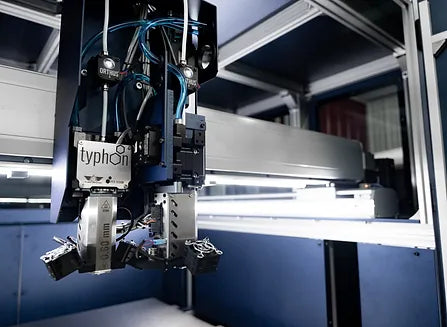

Choose your extrusion system! Equipped at the $125,000 price point is a pellet and a high-flow filament system on the gantry. Perhaps you just want a system? Maybe a dual extrusion high-flow system? Everything can be customized to suit your needs at the time of order.

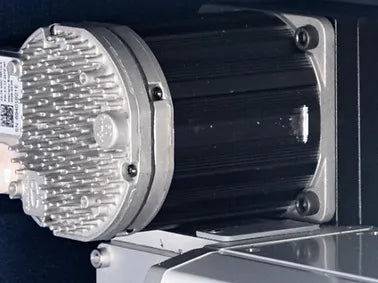

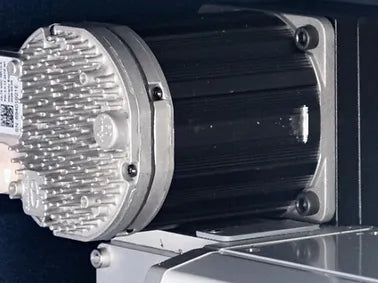

It is time for servo motors to be adopted into 3D Printing, and Filament Innovations has done it. Our X and Y linear motion systems are ran by Teknic, American Made, servos allowing for 500mm/s travel speeds on a reinforced high-speed belt system. Closed-Loop, Leadshine NEMA34s, are used to power the four Z axis enclosed ballscrews.

The POSEIDON is powered by a 220/240VAC, 50amp, Single Phase, electrical system. Everything is then breaker protected for the safety of the user and equipment. This one electrical connection powers everything the machine needs, including the 25kg pellet dryer. You will find a quick disconnect electrical plug and cord located on the outside of the machine. And yes, the cord is included!

On-board filament storage is included for every machine on a convenient sliding drawer platform. Simply slide the drawer out and you'll have room to place two of our 4.5kg spools. For pellets, these are stored in the external 25kg dryer. Please note that the facility must provide a 100PSI compressed air line for both drying and venturi pellet feeding.

A genuine BOFA Fume Extraction system is included with every POSEIDON printer. By including this fume extraction system, we ensure that fumes are internally filtered inside the machine and warm air is kept inside. This allows for safer and more efficient 3D Printing.

Two LCD Screens are included with the system, the 7" PanelDue from Duet3D, and a 15" touchscreen with a more intelligent display. Now you can fully utilize your machine by being able to visualize your height-map, write custom macros on the fly, and better monitor your system. File transfer and connecivity options include USB jump-drive, WiFi, and hardwired Ethernet.

3D Printing will open the doors to new materials being used, and with these new materials will come the need for different build plates. Our relationship with BuildTak will solve many of these issues, but our line-up also includes Powder Coated PEI for more durability. A G10/FR4 plate can also be used in lieu of the magnetic spring steel options.

Below you will find the technical specifications of the machine:

- Machine Size (W,D,H): 92"x70"x88" with 3.2mm Aluminum Panels & Acrylic Windows

- Build Area (XYZ): 1060mm x 1080mm x 1050mm

- Weight: ~2000lbs

- Motors: Teknic Servos

- Extrusion: Pellet (FGF) Pulsar and Typhoon (FDM) High-Flow - both with hardened nozzles

- Motion: High Speed Belt System

- Print Surface: PEI, Buildtak, G10/FR4, Steel

- Print Plate: Magnetic Spring Steel

- Max Nozzle Temp: 450C

- Water Cooling: On-Board S&A CW-3000

- Filament and Pellet Run Out Sensors

- Bed Leveling: Four Z Axis Tilt & Mesh

- Electronics: Duet 3 Ecosystem

- Heated Bed: 120C

- Power: 220/240VAC with 50amp requirement

- ODIN Slicing Software

- Pellet/Filament Type: PLA, PETG, ABS, Nylon, TPU, TPC, ASA, PVA, HIPS, BVOH, PC, PET, Carbon Fiber Reinforced, Fiber Reinforced, Wood Reinforced, etc.

Please note - all POSEIDONS are built to order with a minimum 16 week standard lead time. Need it sooner? Please contact us to see how we can accomodate you. Shipping is handled via private freight carrier. The customer needs to have a forklift on-site to assist in delivery of the machine.