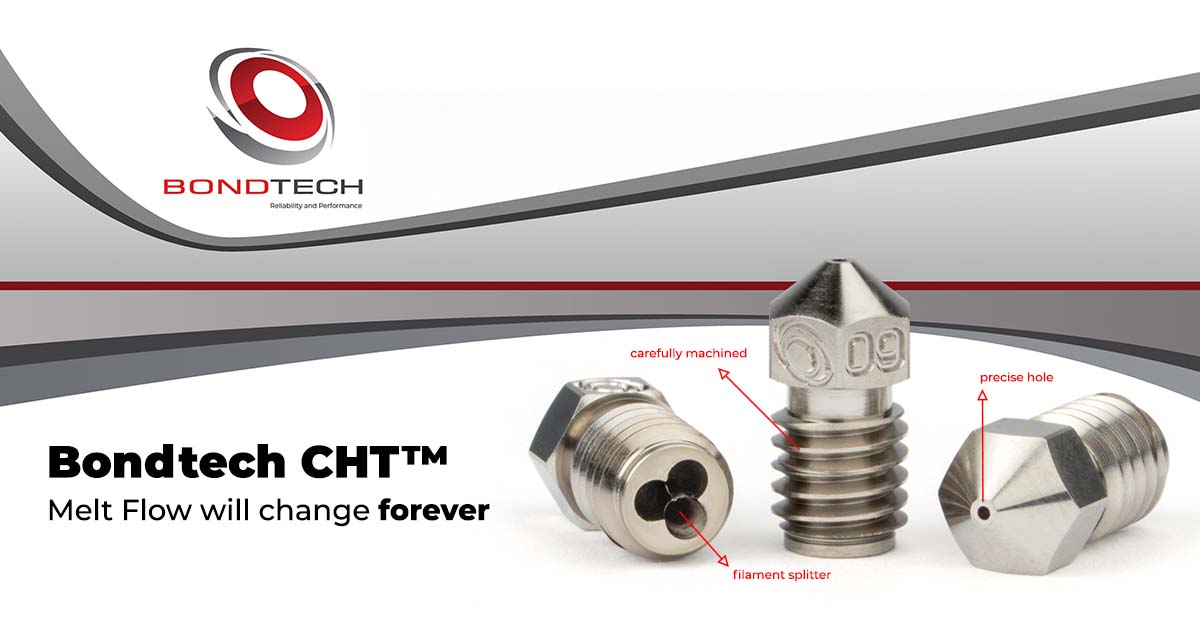

Bondtech CHT High Flow Nozzles (M6 RepRap)

Description

Description

Bondtech CHT® Coated Brass Nozzle

Main Bondtech CHT® Advantages

- Higher melt capacity by increasing the surface area of the heating walls

- Affordable price

- Machined with ultra-precision

- Brass nozzle with Nickel coated surface

- Follows nozzle standards:

- RepRap (M6×1×7.5×12.5)

- MK8 (M6×1×5×13)

- May be used with 1.75 or 2.85mm hotends.

Advantages of the Bondtech CHT® technology:

Bondtech CHT® nozzles split the filament into 3 thinner strands allowing to melt the material from within. In doing so, the material melts faster and higher flow rates can be used.

Advantages of the Nickel Coating

A Nickel coating is applied to our Coated Brass nozzles to provide protection against corrosion, erosion, and abrasion. Nickel coated nozzles have more corrosion resistance and lower coefficient of friction, which allows slicker feeding of material and delays plastic adhesion to the nozzle's surface.

Compatible with the following hotends/blocks:

- Mosquito® / Magnum

- Mosquito® Liquid

- Mosquito® Magnum+

- Copperhead™

- E3D V4, V5 and V6 blocks

- E3D Chimera and Kraken

- RepRap M6