Description

Description

Bambu PLA-CF Filament

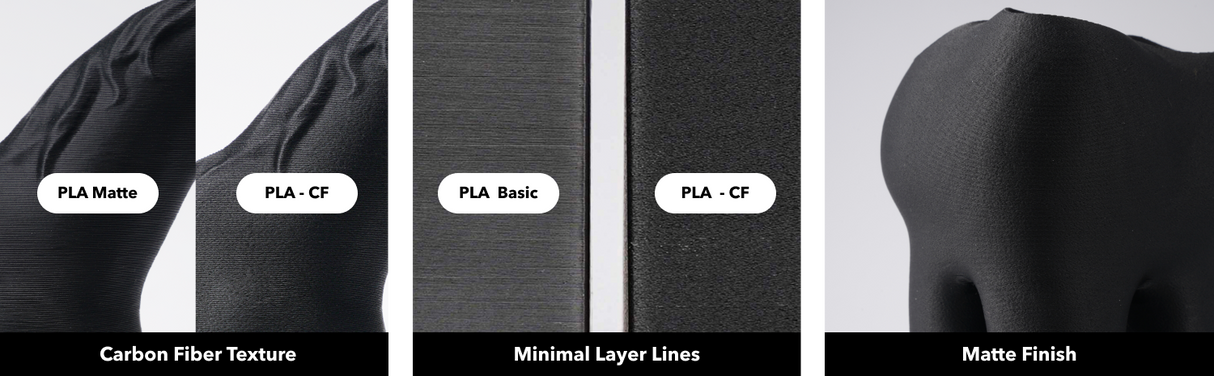

Bambu PLA-CF is carbon fiber reinforced PLA with improved stiffness and strength. PLA-CF is easy to print and beginner-friendly like regular PLA. It is AMS compatible with low clogging risk at high-speed printing. The prints are in matte finish with almost invisible layer lines, which make it suitable for printing general engineering parts or models requiring a better appearance, like bike frames, brackets and toys.

Improved Mechanical Properties

Bambu PLA-CF exceeds the mechanical properties of PLA Matte in XY Bending Strength, Z Bending Strength, XY Bending Modulus, Z Bending Modulus, XY Impact Strength, and Z Impact Strength by between 20% and 115%, making it more suitable for printing models with higher strength requirements.

| PLA Matte | PLA-CF | Improved % | |

| Tensile Strength - XY/MPa | 32 | 38 | 19% |

| Tensile Strength - Z/MPa | 25 | 26 | 4% |

| Bending Strength - XY/MPa | 53 | 89 | 68% |

| Bending Strength - Z/MPa | 32 | 49 | 53% |

| Bending Modulus - XY/MPa | 2360 | 3950 | 67% |

| Bending Modulus - Z/MPa | 2040 | 2260 | 10% |

| Impact Strength - XY/(kJ/m²) | 19.2 | 23.2 | 20% |

| Impact Strength - Z/(kJ/m²) | 6.6 | 7.8 | 18% |

NOTE: Drying PLA is recommended for humid environments at 55 °C for 8 hours before printing.

Stabilized Printing Dimension. Bambu PLA-CF features low shrinkage and warping resistance to achieve a perfect matching accuracy between prints parts.

Minimal Effort in Support Removal. Bambu PLA-CF is designed to support itself. It can be removed more easily compared to regular PLA, and still maintains a smooth support surface.

Not Prone to Clogging in High-Speed Printing. Bambu PLA-CF is just as easy to print as regular PLA. It can be printed smoothly and consistently at high speed without clogging.

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 55 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 210 - 240 °C |

| Bed Temperature (with Glue) | 35 - 45 °C |

| Printing Speed | < 200 mm/s |

| Physical Properties | |

| Density | 1.22 g/cm³ |

| Vicat Softening Temperature | 69 °C |

| Heat Deflection Temperature | 55 °C |

| Melting Temperature | 165 °C |

| Melt Index | 3.7 ± 0.6 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 38 ± 4 MPa |

| Breaking Elongation Rate | 8.4 ± 3.2 % |

| Bending Modulus | 3950 ± 190 MPa |

| Bending Strength | 89 ± 4 MPa |

| Impact Strength | 23.2 ± 3.7 kJ/m² |