Description

Description

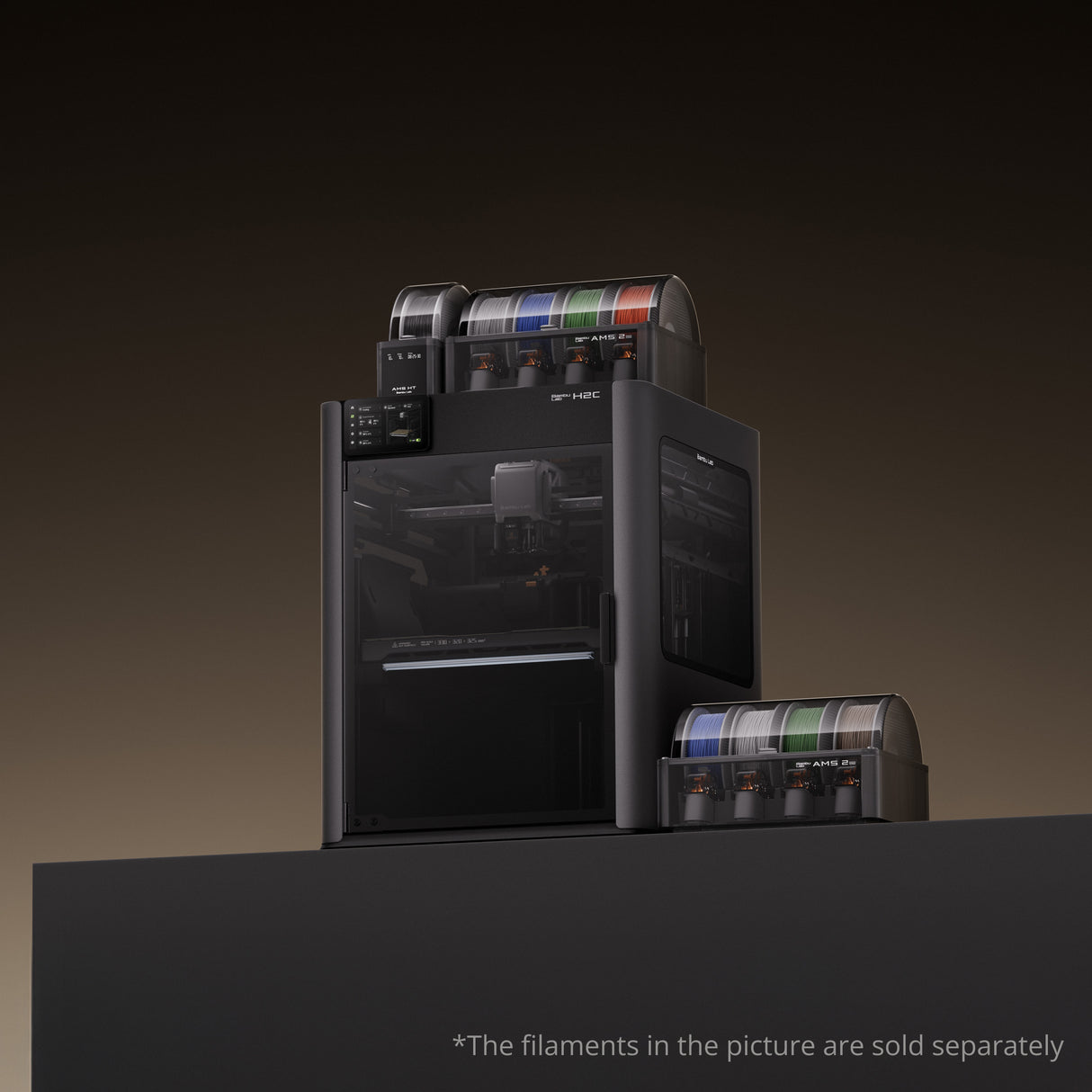

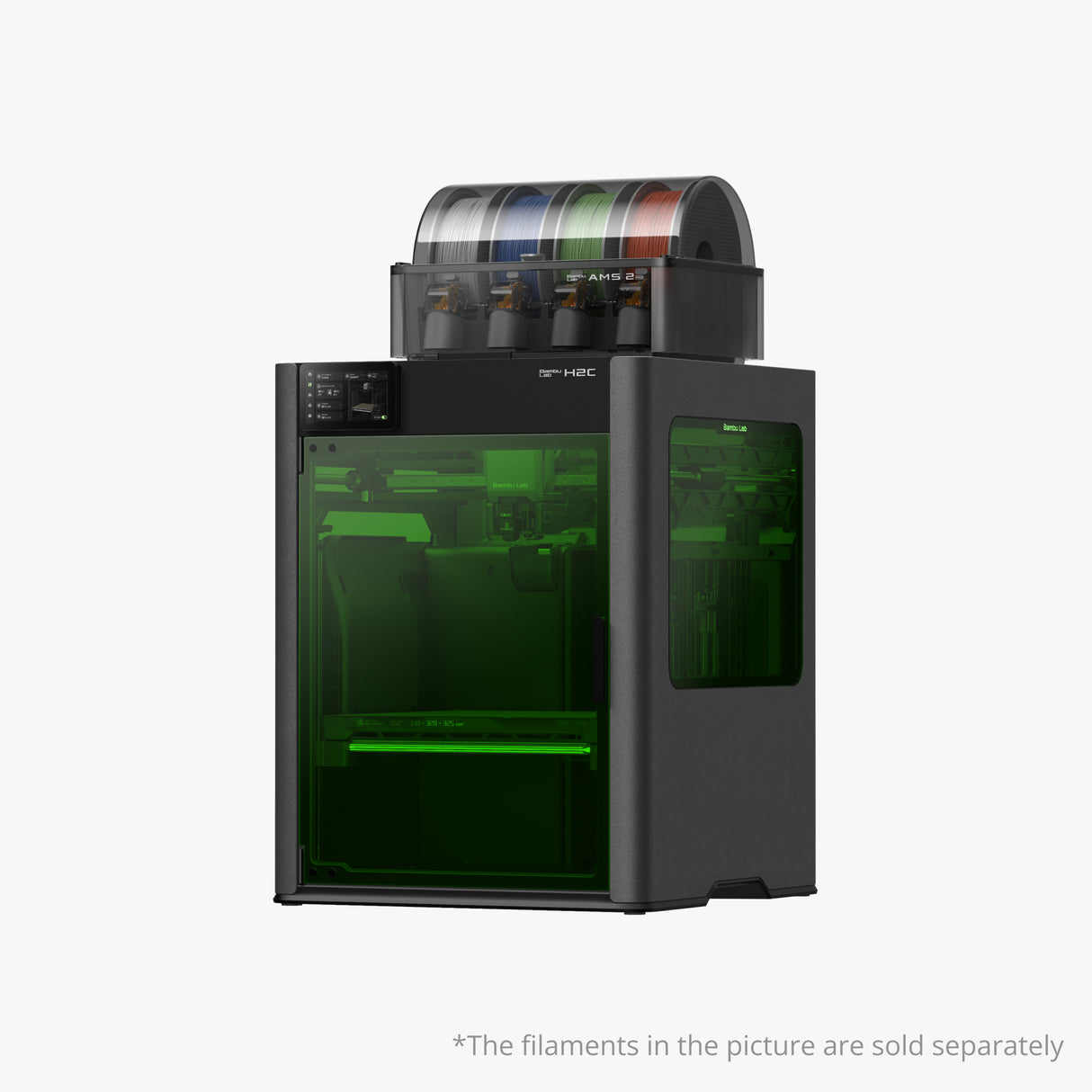

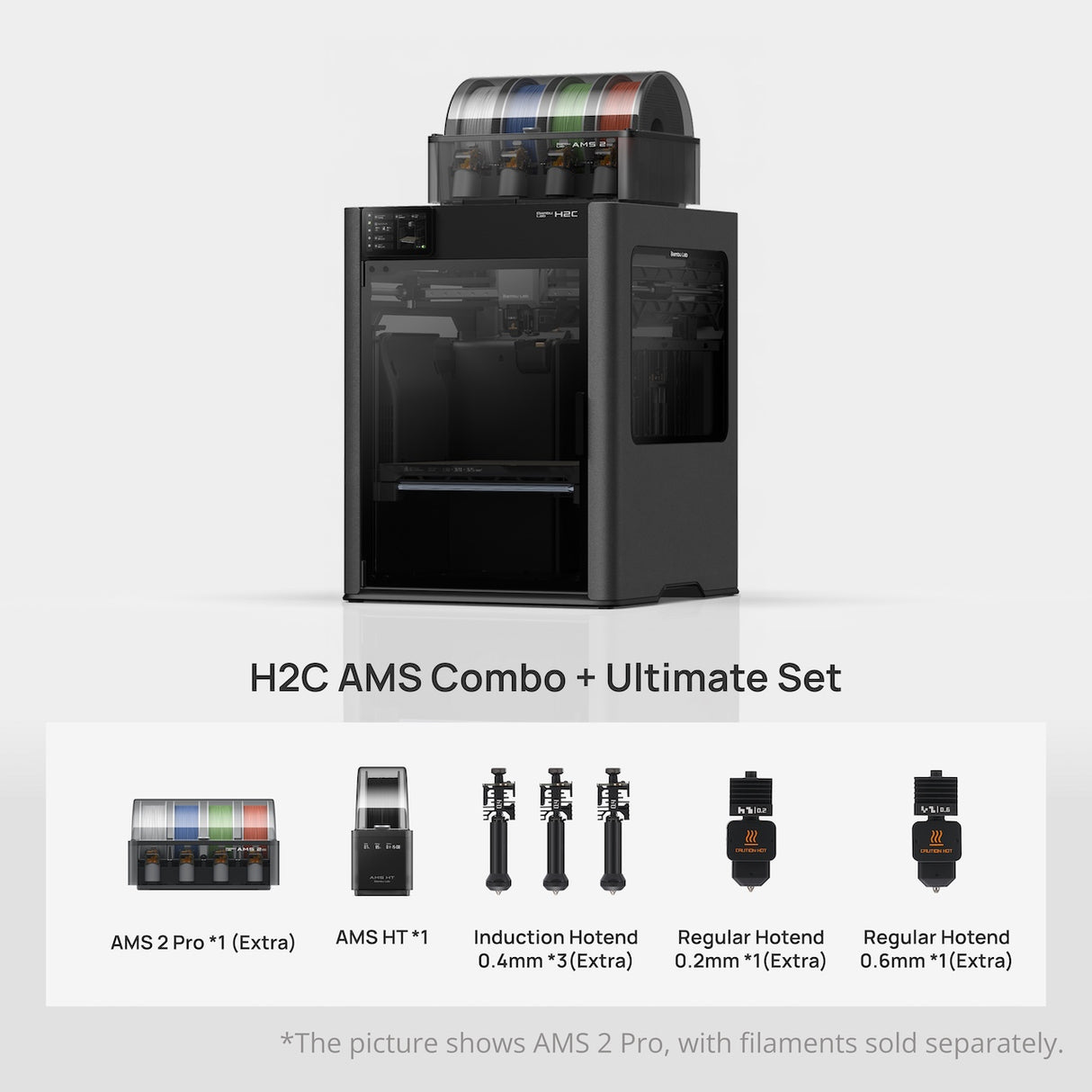

Bambu Lab H2C 3D Printer with Hotend Changer

Uncompromising Multi-Material.

- Hotend Change Multi-material Printing

- Minimal Purge Waste Multi-Color Printing

- Precise & Fast Inductive Nozzle Heating

- Close-loop Servo Extruder

- Full Filament Path AI Error Detection

- 350°C Nozzles & 65°C Active Heated Chamber

- Optional 10W/40W Laser and Cutting Module

- 330*320*325 mm³ Build Volume

Cybersecurity compliant with EU RED Article 3.3(d)(e). Learn more.

- To get the most out of the H2C, you’ll need at least two 4-slot AMS units and six matching induction hotends. The Ultimate Set includes these and adds extra hotends for expanded use.

- Your order may be shipped in separate packages and arrive at different times. Please refer to the FAQ for details on how your specific configuration will be delivered.

Why Buy a Bambu Lab Printer From HartSmart Products?

HartSmart Products (HSP) is more than just an authorized reseller of Bambu Lab printers, parts, accessories, and filament. HSP is also an authorized Repair Center and even an authorized Warranty Center for Bambu Lab. If anything goes wrong with your printer we're able to get customers up and running quickly with our Iowa, USA team and inventory of warranty parts. You simply get more when you buy from HSP!

- H2C: 532g

- H2D: 3032g

- H2S: 3917g

No More Assembly - Print Multi-Material Parts in One Piece.

Purge Saving Multi-Material Printing

With the H2C, you can print up to seven different materials in a single run — no nozzle purging required. Combine multiple material properties in one seamless structure and take integrated design to a whole new level.

Materials in this Drone Model:

- PA6-GF for Structural Rigidity

- TPU for AMS for Impact Absorbing

- PC-FR for Fire Redardancy

Print Durable Joints - Built Right Into the Parts

Integrated TPU Joints for Multi-Color Parts

Print Durable TPU ball joints for your robot models--flexible, long-lasting, and built for endless motion.

Multi-Material Printing with Minimal Purge Waste

Fully Automatic Filament Change

Always Delivery the Most Efficient Combination

Why Vortek?

Small Form Factor, More Filaments

8-Second Induction Heating

Contactless Design for Reliability

Colors are No Longer Limited by How Many Toolheads You Have

Enclosed for High-Performance Printing

Fully Automatic Nozzle Offset Calibration

Dedicated Hotends for Specific Filaments

Not A Toy. A Serious Production Powerhouse.

Better High-Speed Reliability & Real-Time Error Detection

The PMSM servo extruder delivers up to 10 kg of maximum extrusion force—70% more than stepper motor—dramatically improves high-flowrate extrusion stability. Our proprietary servo architecture samples resistance and position at 20 kHz, actively detecting filament grinding and clogs in real time.

50 µm Ultra-Fine Motion Accuracy

With its Vision Encoder, the H2C achieves a distance-independent motion accuracy of less than 50 μm—thinner than human hair. The system automatically compensates for any mechanical drift during calibration, ensuring consistent precision and peak performance over time.

Smooth Surface, Sharp Edges

The H2C leverages both the servo motor on the extruder and the high-resolution eddy current sensors on the nozzle to sense extrusion dynamics. This enables precise extrusion control and automatic calibration of Pressure Advance (PA) parameters for each filament, resulting in smoother surfaces and cleaner, sharper edges.

H2C Specifications

| Item | Specifications | |

| Printing Technology |

Fused Deposition Modeling

|

|

| Body | Build Volume (W*D*H) |

Single Nozzle Printing: 325*320*320 mm³ (Left)

Single Nozzle Printing: 305*320*325 mm³ (Right)

Dual Nozzle Printing: 300*320*325 mm³

Total Volume for Two Nozzles: 330*320*325 mm³

|

| Chassis |

Aluminum and Steel

|

|

|

Outer Frame

|

Plastic and Glass

|

|

| Physical Dimensions | Physical Dimensions |

492*514*626 mm³

Recommended Space for Printer: 700mm*700mm*1100mm

|

| Net Weight |

32.5 kg

|

|

| Toolhead | Extruder Gear | Hardened Steel |

| Nozzle | Hardened Steel | |

| Max Nozzle Temperature | 350 °C | |

| Supported Nozzle Diameter | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm | |

|

Filament Cutter

|

Built-in

|

|

| Filament Diameter | 1.75 mm | |

| Extruder Motor | Bambu Lab High-precision Permanent Magnet Synchronous Motor | |

| Heatbed |

Build Plate Material

|

Flexible Steel Plate

|

|

Included Build Plate Type

|

Textured PEI Plate

|

|

Download Technical Specifications PDF

What's In The Box?

| H2C AMS Combo | H2C Laser Full Combo | Ultimate Set | |

|---|---|---|---|

|

H2C

|

1 | - | - |

|

H2C Laser Edition

|

- | 1 | - |

|

Build Plate

|

1 | 1 | - |

|

Spool Holder

|

1 | 1 | - |

|

0.4mm Induction Hotend

|

4 | 4 | 3 |

|

0.2mm Induction Hotend

|

1 | 1 | - |

|

0.6mm Induction Hotend

|

1 | 1 | - |

|

0.4mm Hardened Steel Hotend

|

2 | 2 | - |

|

0.2mm Stainless Steel Hotend

|

- | - | 1 |

|

0.6mm Hardened Steel Hotend

|

- | - | 1 |

|

4-in-1 PTFE Adapter II

|

1 | 1 | - |

|

Accessory Box

|

1 | 1 | - |

|

AMS 2 Pro

|

1 | 1 | 1 |

|

AMS HT

|

- | - | 1 |

|

10W Laser Module

|

- | depending on option | - |

|

40W Laser Module

|

- | depending on option | - |

|

Cutting Module (with Pen holder)

|

- | 1 | - |

|

Laser Platform

|

- | 1 | - |

|

Cutting Platform

|

- | 1 | - |

|

Emergency Stop Button

|

- | 1 | - |